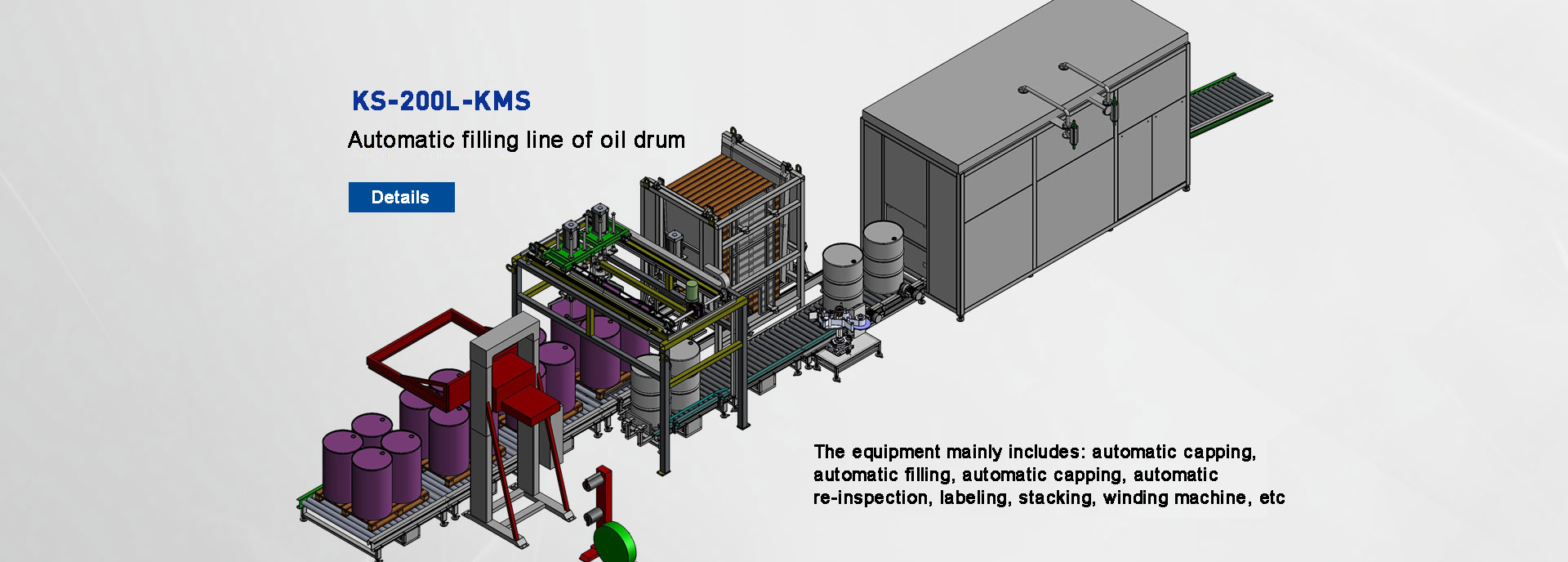

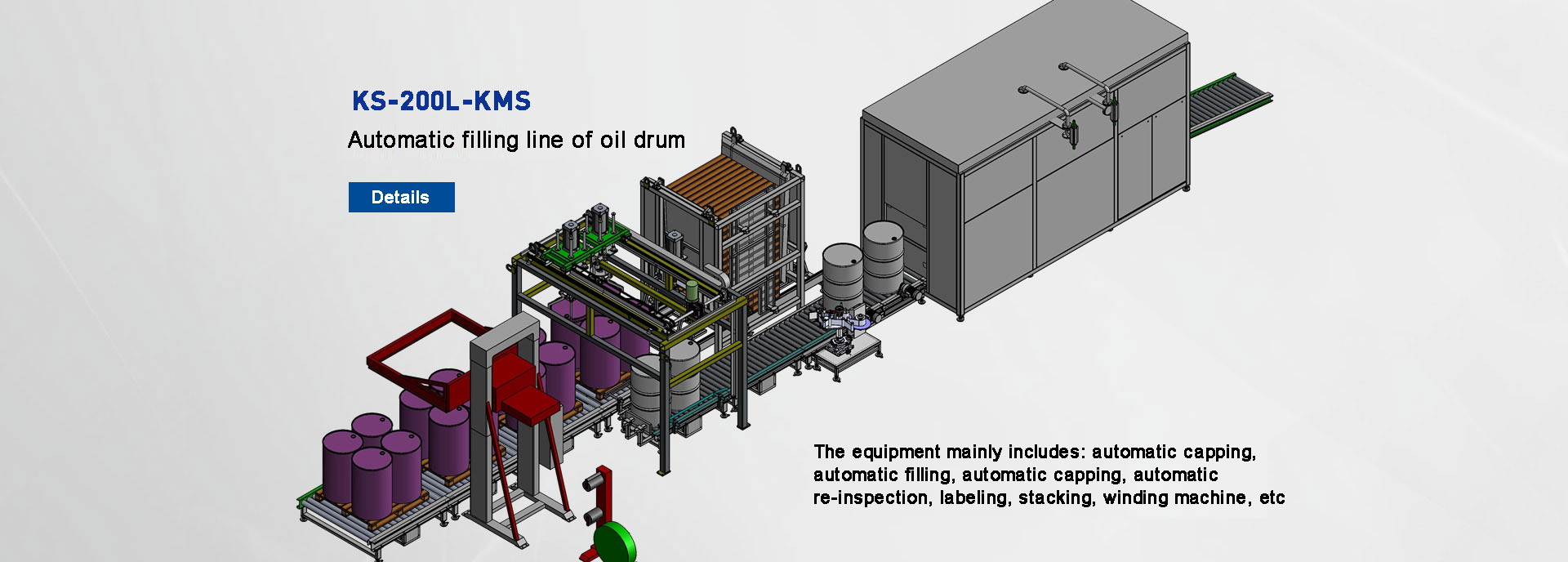

Thinner Filling Machine - 200L Foam-Compatible High-Precision Filling Equipment

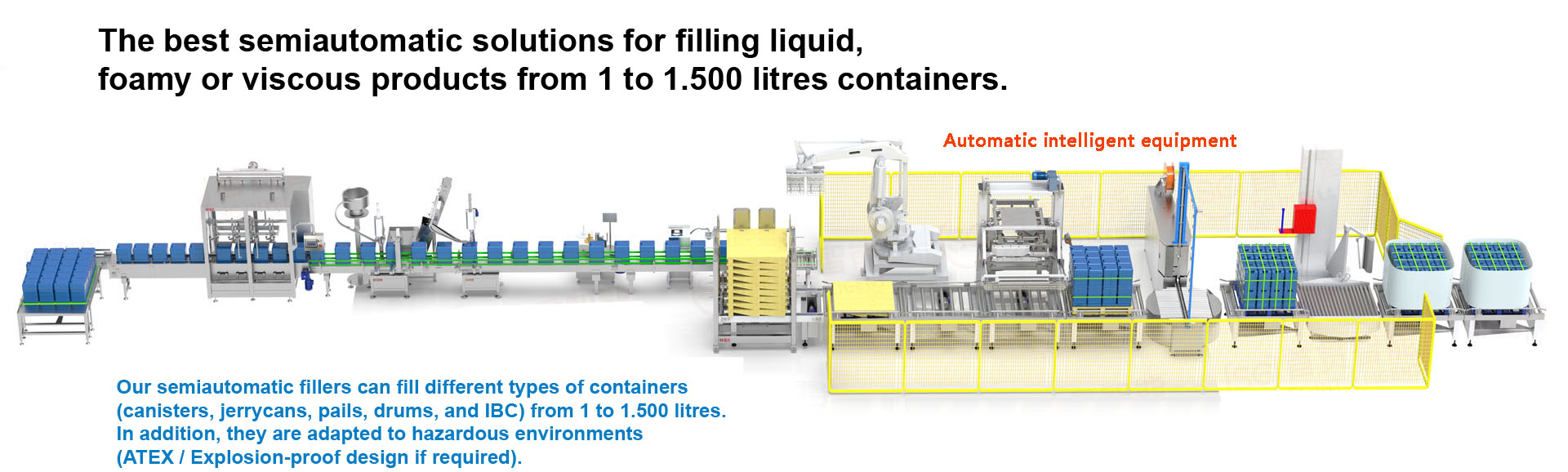

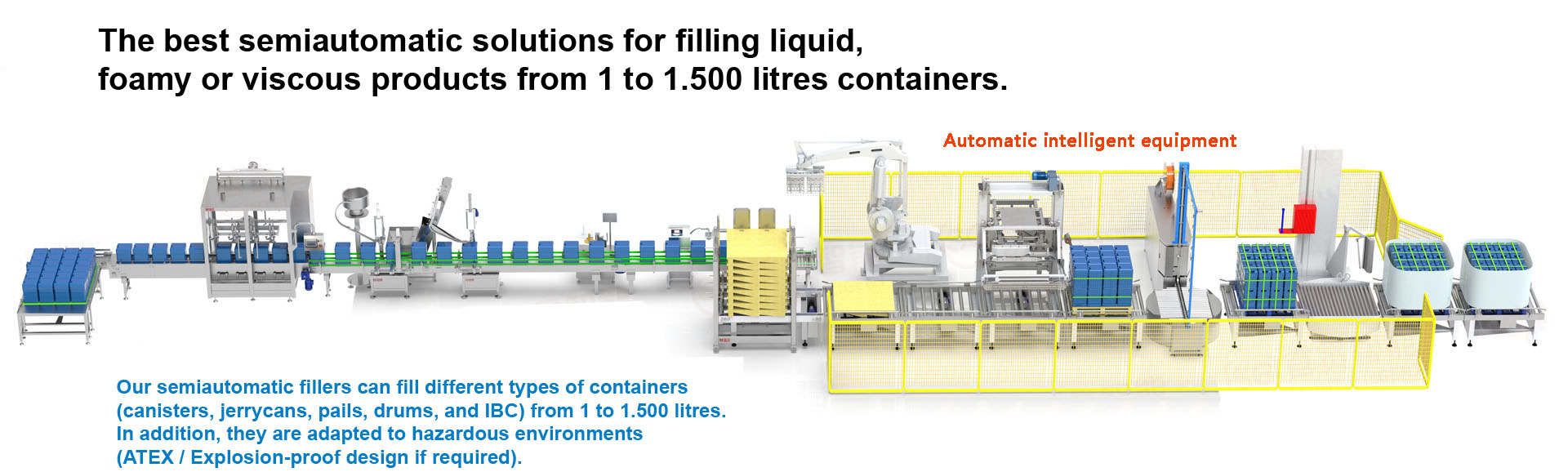

Shanghai Guangzhi Automation Equipment Co., Ltd. specializes in manufacturing and selling liquid packaging equipment including automatic food additive fillers, fermentation fertilizer fillers, quantitative weighing fillers, foam-free fillers, and chemical fillers. These systems are widely used in food, pharmaceutical, and cosmetics industries. Driven by customer needs, technological innovation, and quality management, we provide optimal solutions.

200L Foam-Compatible High-Precision Thinner Filling Machine – Technical Specifications

Max. Weighing Capacity: 200KG

Min. Sensitivity: 60KG

Filling Accuracy: ±0.1%

Control Mode: 2-stage speed control

Filling Method: Submerged filling (nozzle insertion)

Nozzle & Tubing: 304 stainless steel nozzle & metal hose

Material: Stainless steel frame, 304 SS contact surfaces

Weighing Platform Size: 1500×1500mm

Pipe Pressure: 0.2-0.6MPa

Air Supply: 8mm quick-connect fitting (customer-provided)

Power Supply: AC380V/50Hz (customer-provided)

Air Pressure: 0.4-0.8MPa (customer-provided)

Explosion-Proof Rating: Non-explosion-proof

Key Features

Auto Barrel Positioning – Simply place the drum on the conveyor.

Vacuum Anti-Drip & Movable Nozzle – Prevents spills and allows flexible positioning.

High-Strength Stainless Frame – Easy disassembly and cleaning.

Touchscreen HMI – Simple weight/speed adjustment with visual operation.

High-Precision Pump – Ensures reliable and accurate dosing.

Dual Leak-Proof Design – Mechanical seal + auto-suction.

Dual-Speed Filling – Fast initial fill followed by slow topping.

Operation Process

Automated conveyor transports empty drums to filling zone.

Post-filling, filled drums move to capping/sealing station.

Optional integration with labeling/palletizing systems.

Applications

? Paints ? Inks ? Adhesives ? Resins ? Lubricants

? Solvents ? Thinners ? Additives ? Pesticides ? Cosmetics

(All free-flowing liquids)

After-Sales Service

Pre-Delivery Notice – 3-day advance notification for inspection arrangements.

On-Site Support – Technical guidance for installation/preparation.

Storage Requirements – Weatherproofing for outdoor storage.

Inspection Options – Factory acceptance or on-site verification per contract.

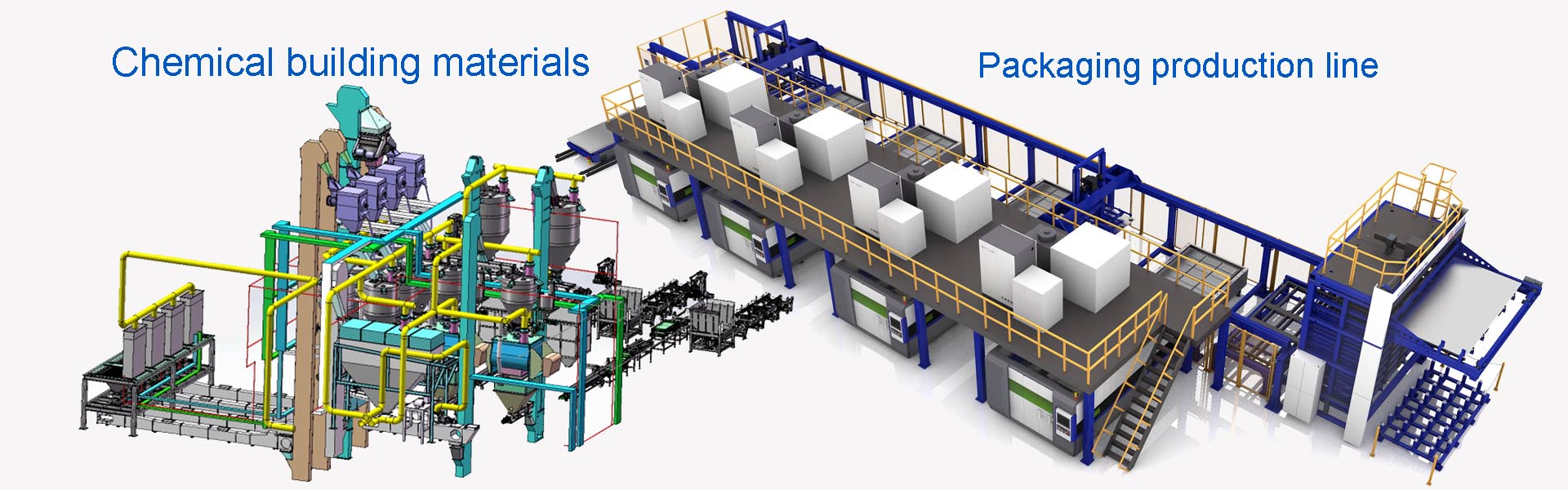

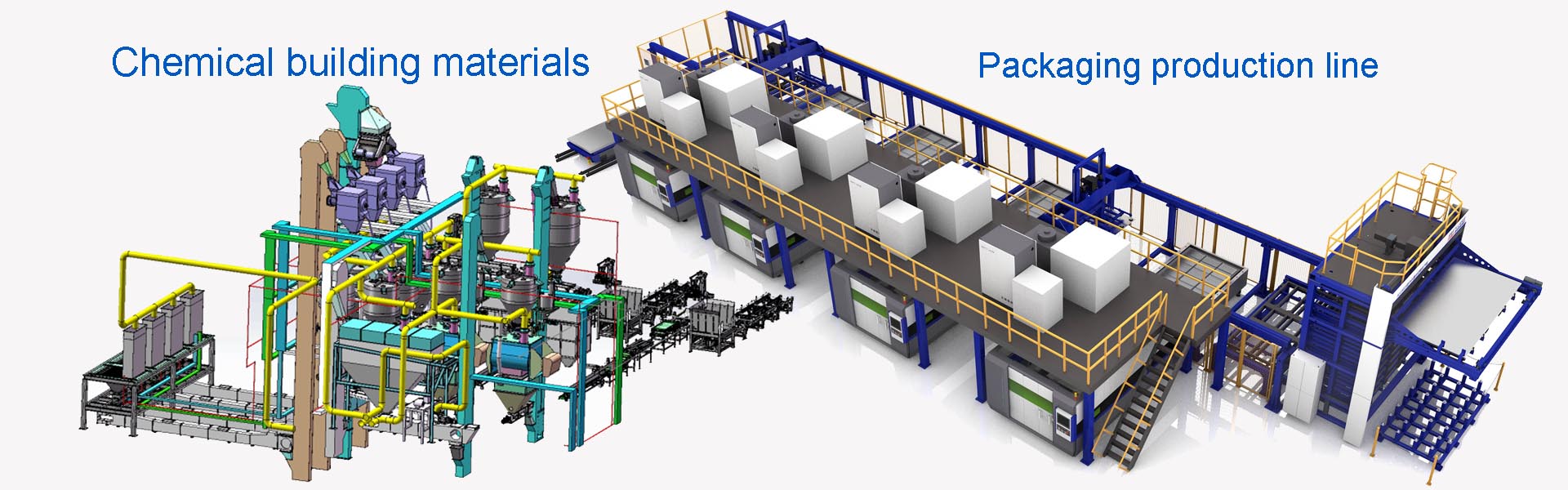

Related Equipment

200L Diesel Drum Filler

200L Disinfectant Packer

220L Corrosion-Resistant Drum Filler

200L Grease Filler (Submerged Type)

220L Water-Soluble Fertilizer Filler (Explosion-Proof)