Dyeing & Printing Auxiliary Agent Filling Machine – 1000L IBC Tote Gravity-Fed Precision Filling System: One-Stop Solution for Accurate Dispensing

Shanghai Guangzhi Automation Equipment Co., Ltd.

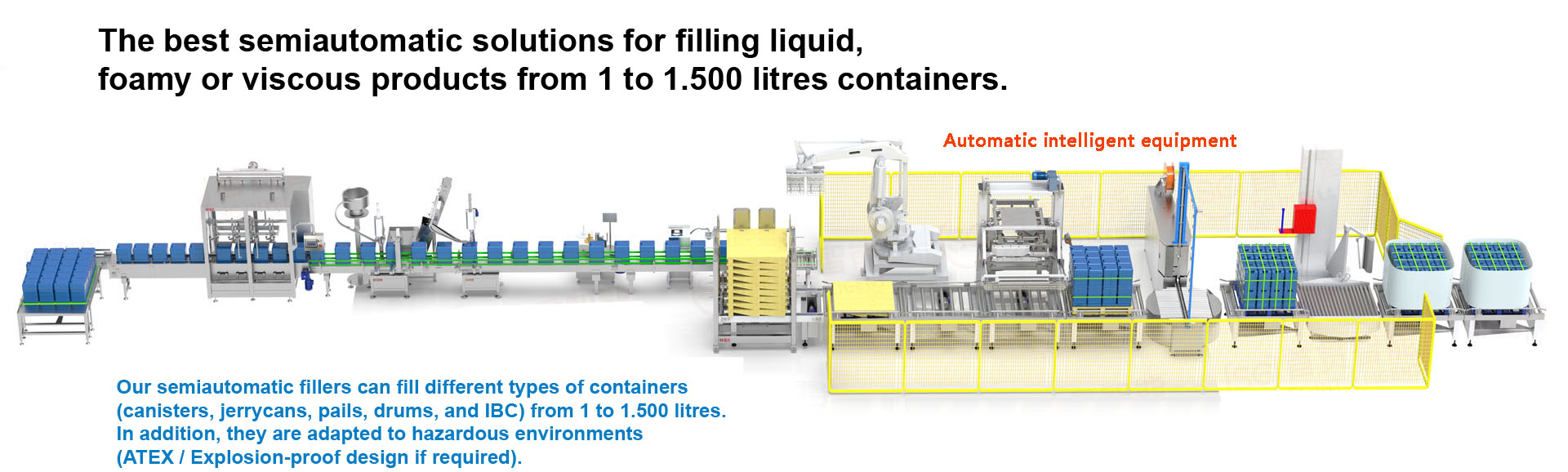

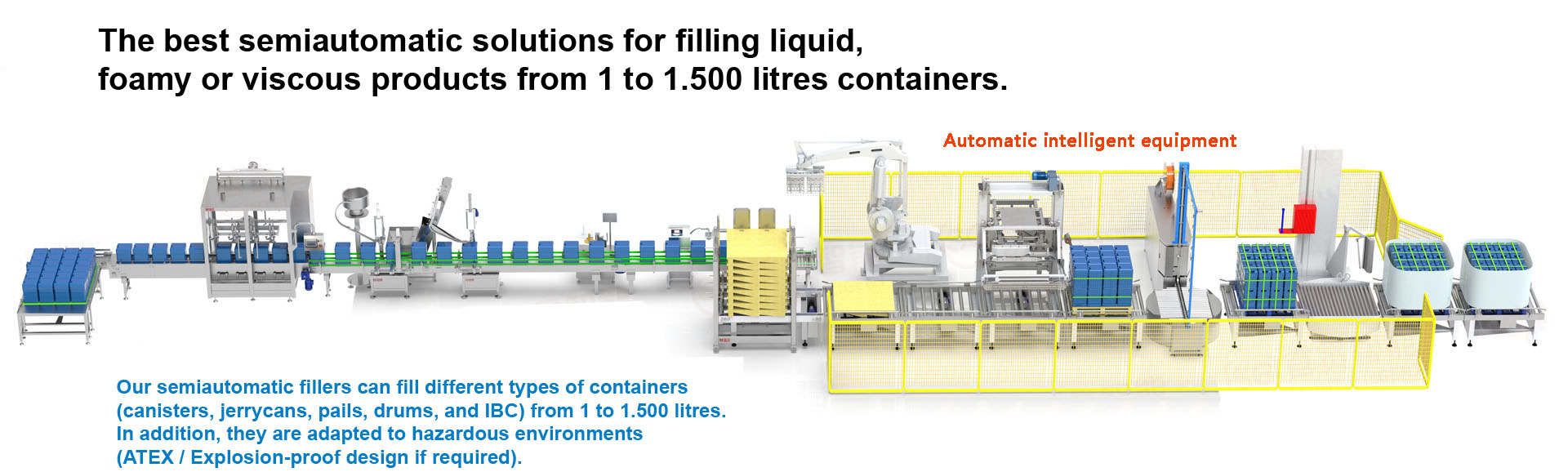

We manufacture and supply high-efficiency filling equipment including:

Hydrazine hydrate fillers

Adhesive filling machines

Polyether fillers

Submerged nozzle fillers

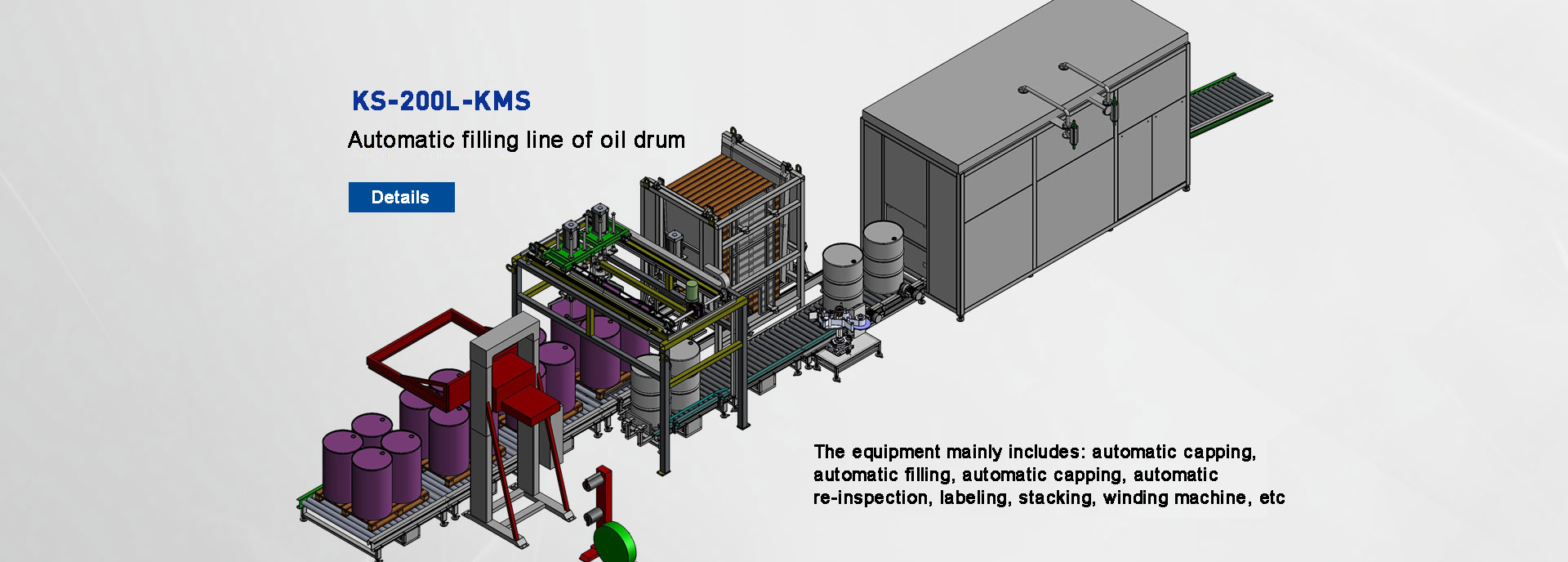

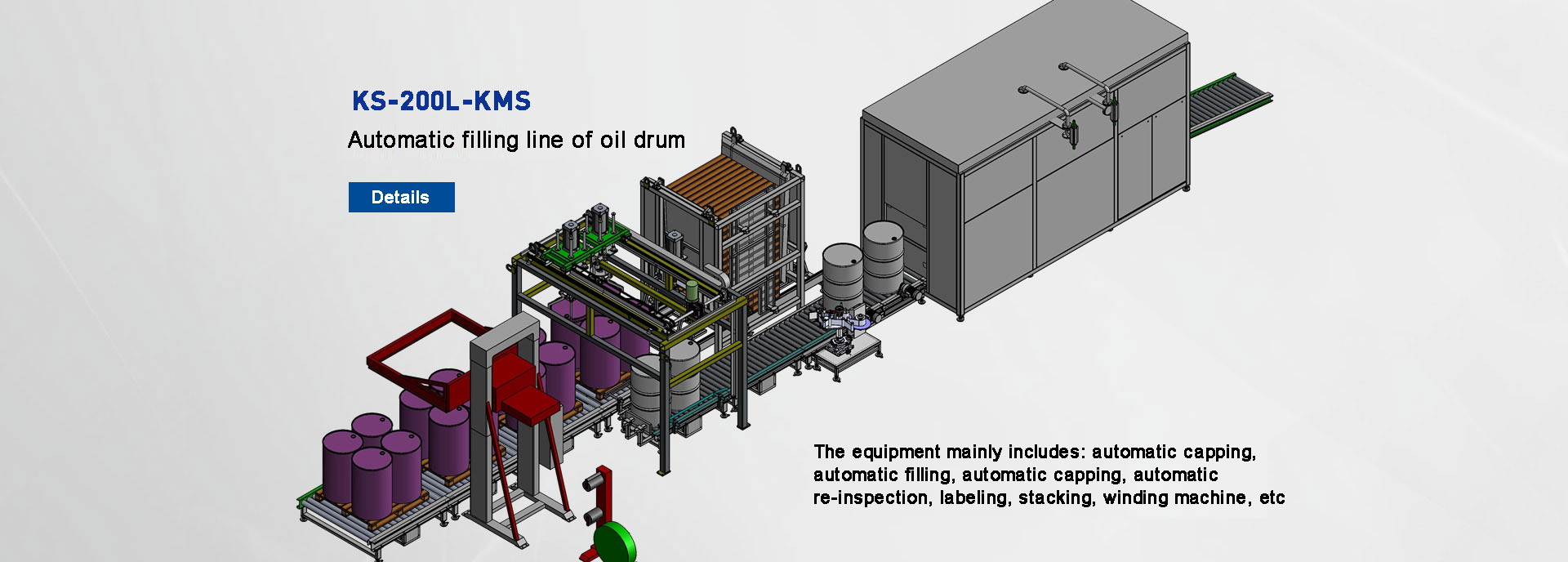

Automatic drum filling systems

Committed to customer-centric innovation, we deliver premium products and services through technological advancement and quality excellence.

Textile Auxiliary Filler – 1000L IBC Tote Gravity Filling System

Technical Specifications:

Capacity: IBC totes (1000L) / 4×200L drums

Accuracy: ±0.1%

Min. Detection: 1kg

Nozzle Material: SUS304 (SUS316 optional)

Container Size: ≤?1200×H1200mm

Power: AC220V/50Hz, 1.0kW

Air Supply: 0.5±0.1MPa, 10m3/h

Temp. Range: -10°C~50°C

Speed: 6-10 totes/hour

Material Inlet: DN50 PN1.6MPa (customizable)

Inlet Pressure: 0.2~0.6MPa (material-dependent)

Key Features:

? Single-nozzle design

? 32-bit dual-core CPU control

? Digital weight input & real-time display

? Stores 10 preset recipes

? Net/gross weight modes

? Auto zero-tracking & two-speed filling

? Dual safety protection (power failure/stop)

? Explosion-proof option

? Auto-lifting nozzle for submerged filling

Operation Process:

Empty totes enter via conveyor; filling chamber doors close automatically.

Nozzle aligns with tote opening, performs tare reset, and fills via 3-stage flow control.

Post-filling, nozzle retracts with drip tray engagement; filled totes exit.

Applications:

Chemical, food, and pharmaceutical industries for IBC totes (1000L), 200L×4 drums, or 60L×12 drums.

After-Sales Service:

? Scheduled maintenance with prepared spare parts

? Minimal downtime & efficient repairs

? Comprehensive post-service guidance

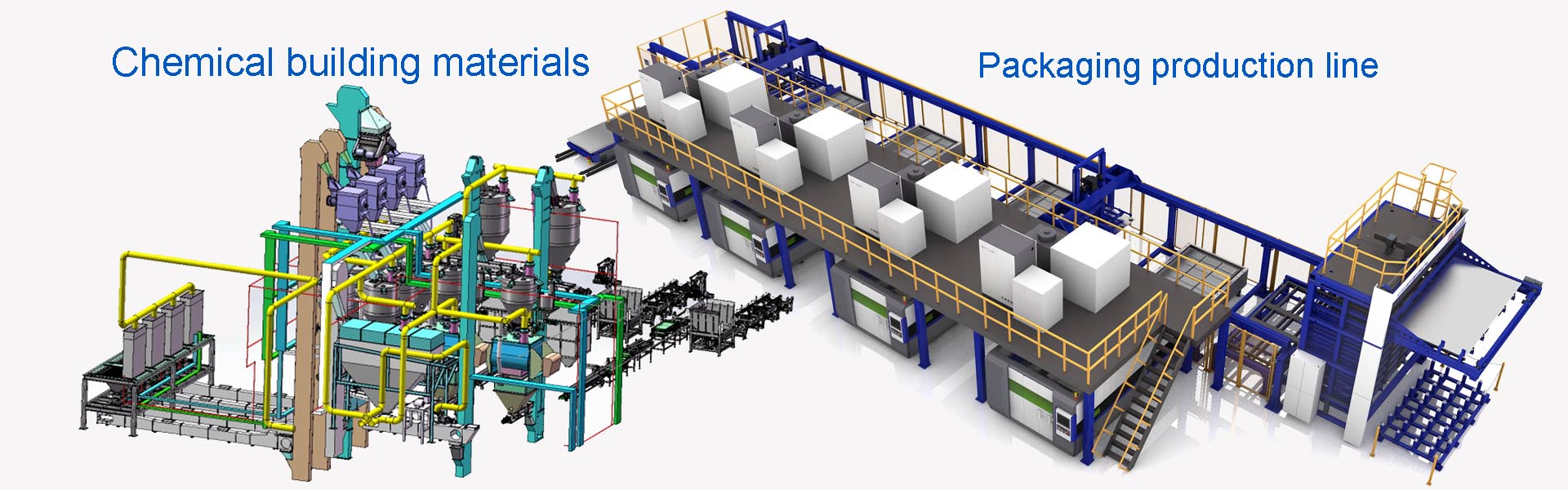

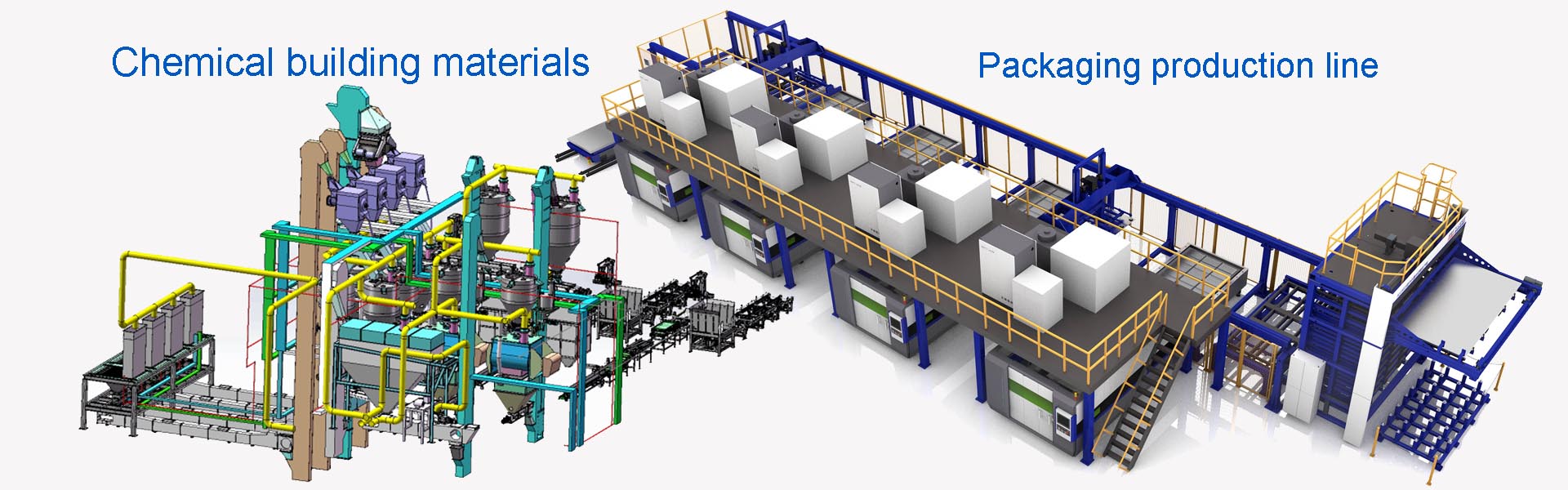

Related Equipment:

1000L Hydrazine Hydrate Filler (Submerged Nozzle)

1200L IBC Tote Filler (Auto-capping)

1000L Sodium Hypochlorite Filler (Explosion-Proof)

1000kg Peanut Oil Filler (Stainless Steel)

1200L Disinfectant Filler (Single-Nozzle)