1000L IBC Tote Swing-Arm Filling Machine - Intelligent Sewing Machine Oil Filler – Simple Operation, Affordable Pricing

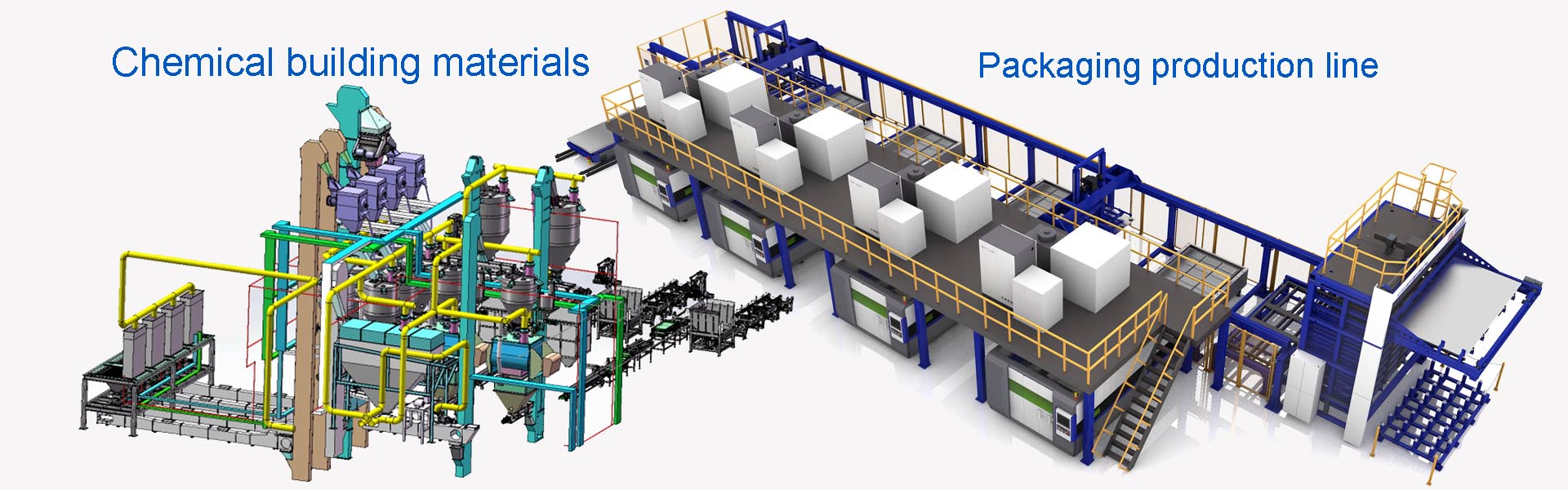

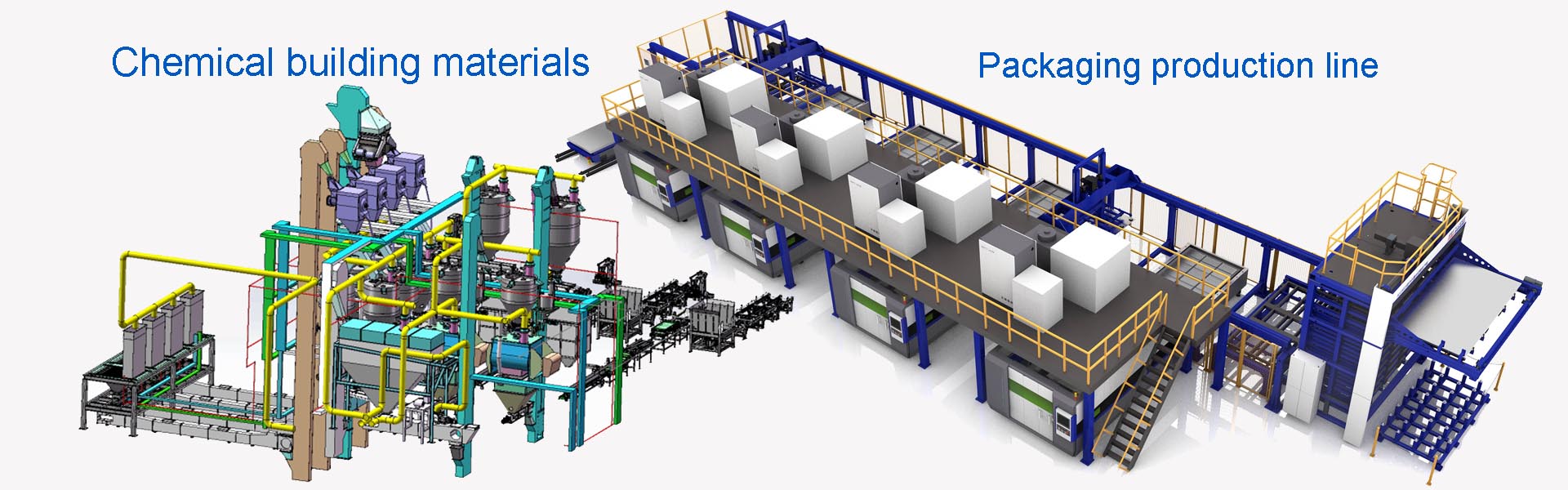

Shanghai Guangzhi Automation Equipment Co., Ltd. specializes in automated packaging solutions for various materials, including flavoring filling machines, waterproof coating fillers, grease filling systems, automatic drum filling machines, and dual-head weighing fillers. Our equipment features high automation and intelligent operation. Centered on customer needs, we continuously enhance technological innovation and quality management to deliver superior products and services.

1000L IBC Tote Rocker Arm Filling Machine (for Sewing Machine Oil) – Intelligent, Easy-to-Operate & Cost-Effective

Technical Parameters:

Filling Range: 1000L IBC totes

Max. Weighing Capacity: 300×4 kg

Min. Sensitivity: 0.1 kg

Filling Error: ≤0.1%

Nozzle Material: SUS304 stainless steel (PTFE-lined)

Container Compatibility: ≤?600×H1000mm

Explosion-Proof Rating: EXdIIBT4

Power Supply: AC220V/50Hz

Air Supply: 0.4-0.8 MPa

Operating Temp.: 10°C-120°C

Control Mode: 3-stage pneumatic control

Filling Method: Top/bottom filling

Material Inlet: DN40 quick-connect fitting (flange optional)

Key Features:

? Compliant with QB/T2501-1000 Gravimetric Automatic Filling Standard

? 316L & PTFE material contact parts for corrosion resistance

? High-end Omron RELAY electrical components

? Pneumatic ball valve prevents leakage when not filling

? PTFE sealing system – resistant to solvents, acids & alkalis

? Insertion-type filling avoids splashing & container contamination

? Two-stage filling (fast + precision) for high accuracy

? Auto-nozzle retraction after filling completion

? Safety interlock – filling only when nozzle is properly inserted

? One-touch operation – place bucket, align nozzle, and press start

? Emergency stop function for instant shutdown

? Nitrogen purging to prevent oxidation

Operation Process:

Power on → Place tote on scale via forklift

Align nozzle using the handle & release brake lock

Press [Start] → Nozzle auto-inserts → Tare weight deducted

3-stage filling (fast → slow → micro-dosing)

Nozzle auto-raises with liquid level → Shuts off at target weight → Retracts

Repeat for up to 4 totes (50GL)

Applications:

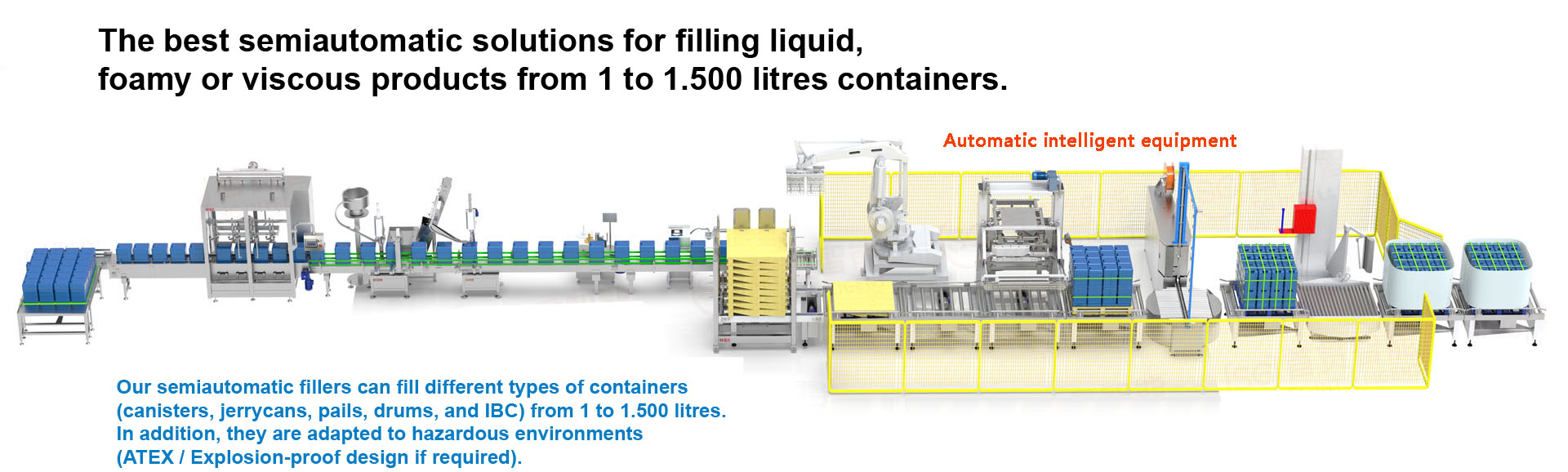

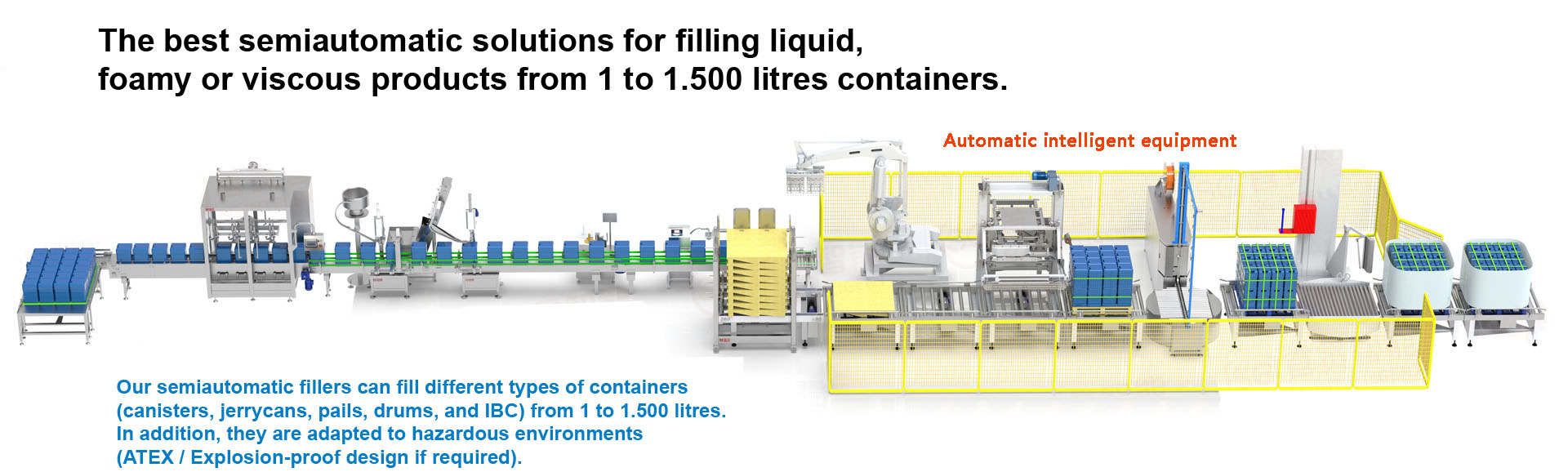

Resin, emulsion, solvents, chemicals, agriculture, food-grade liquids, and more.

After-Sales Service:

We provide premium maintenance with rapid fault detection and resolution. Our expert team, stocked with spare parts, ensures minimal downtime. Committed to excellence, we guarantee satisfaction!

Related Equipment:

1000L Tote Urea Packing Line (Dual-Speed)

1200kg IBC Phosphoric Acid Filler with Conveyor

1000kg Tote Adhesive Drum Filler (Pneumatic)

1000L IBC Alcohol Drum Filling & Capping Station