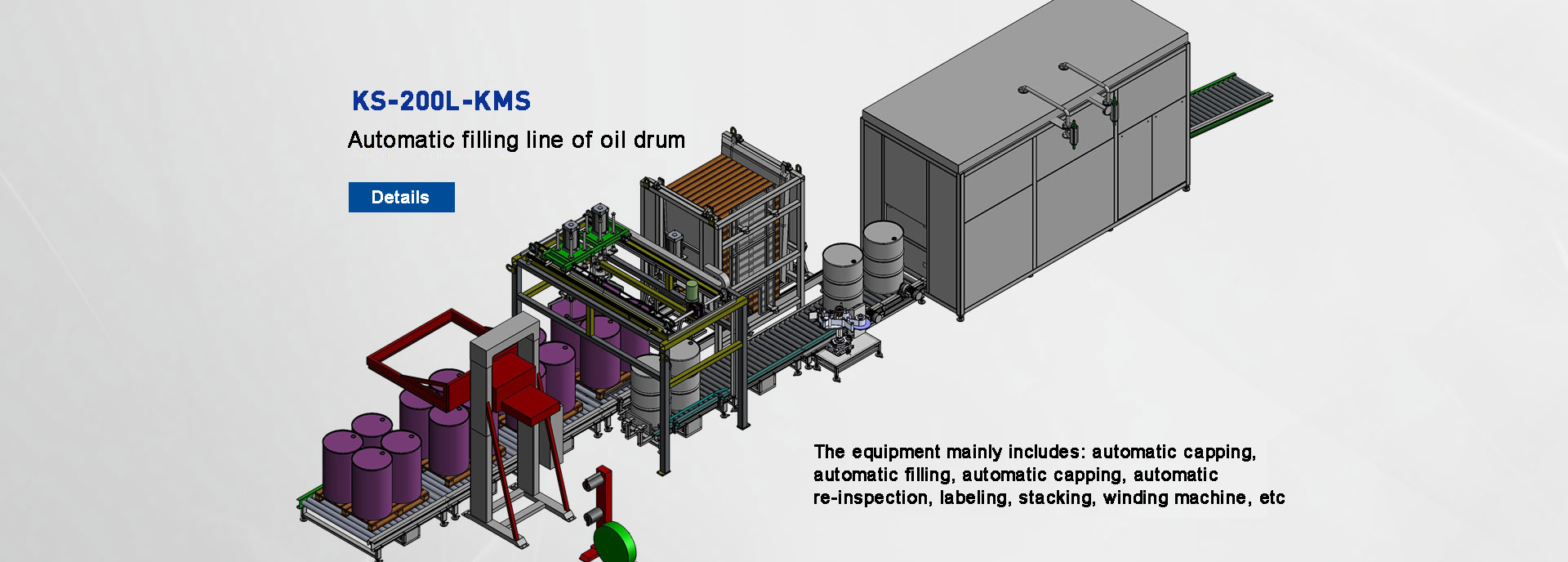

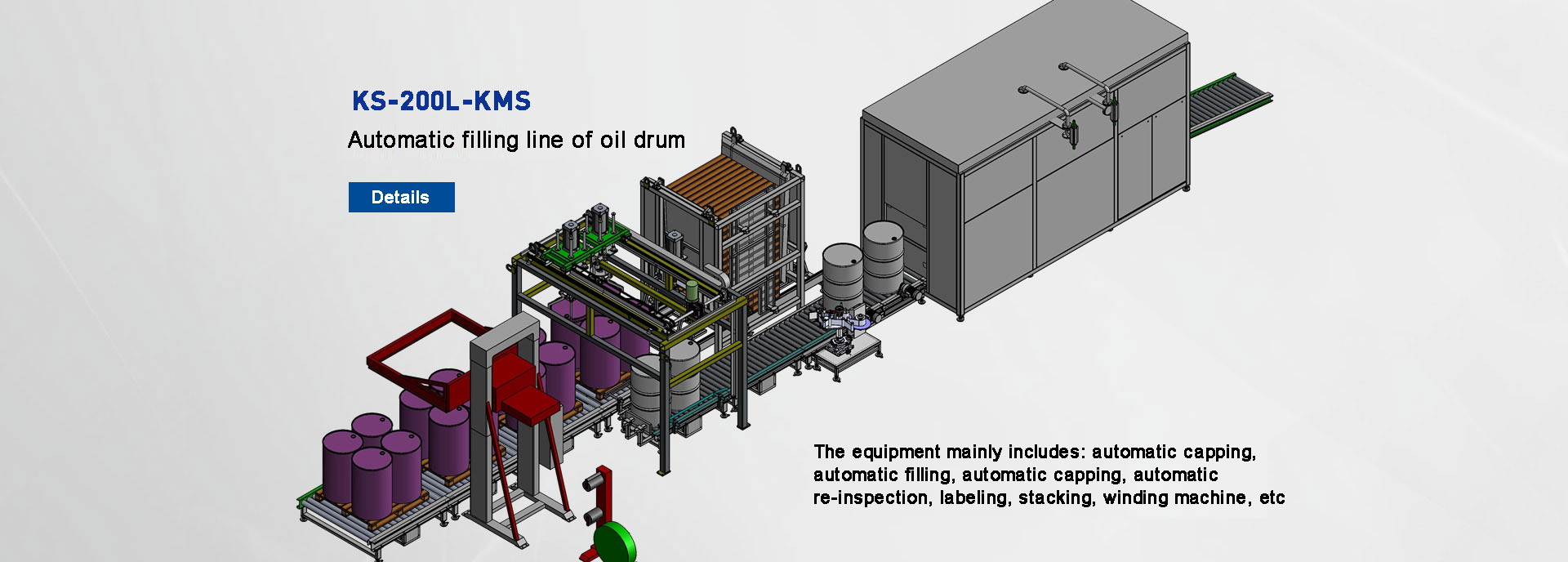

200KG Automatic Filling Machine_Adhesive Filling Machine_High Efficiency, High Precision, Safety & Reliability

Multi-Functional Automatic Filling Machine - 200kg Filling Machine - Hardener Filling Machine

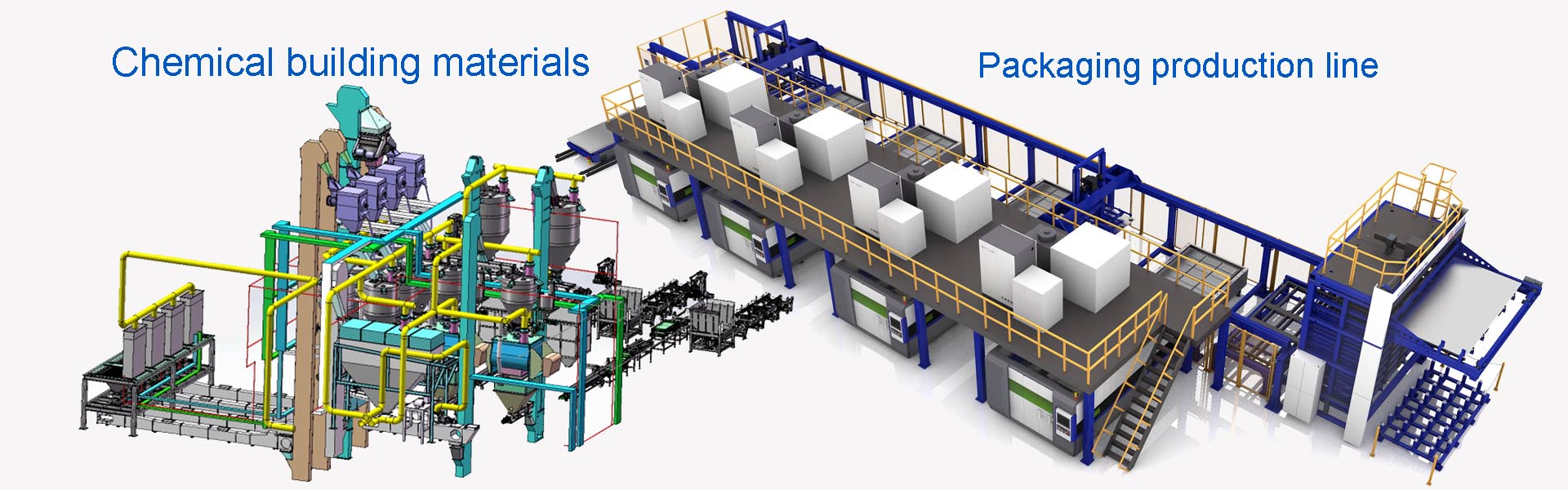

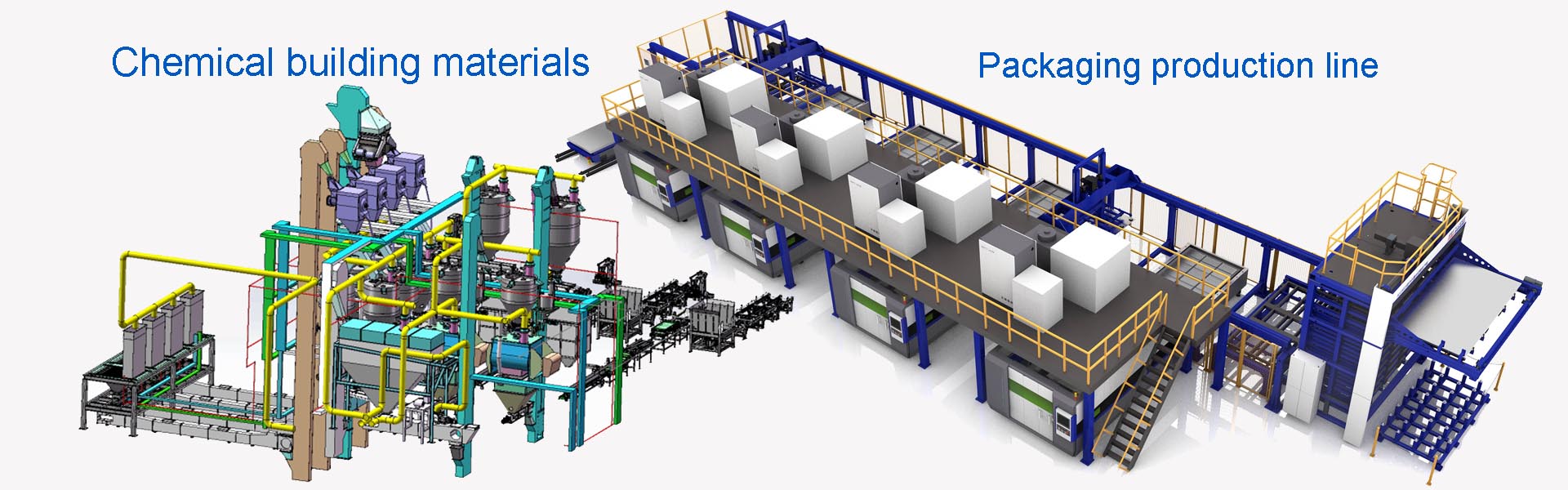

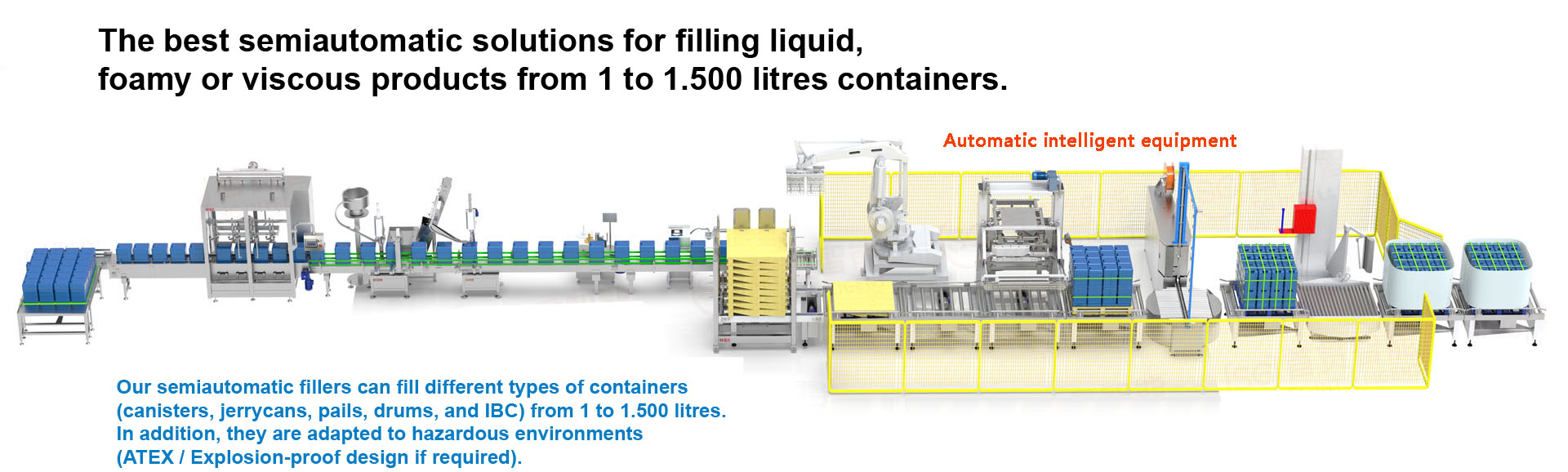

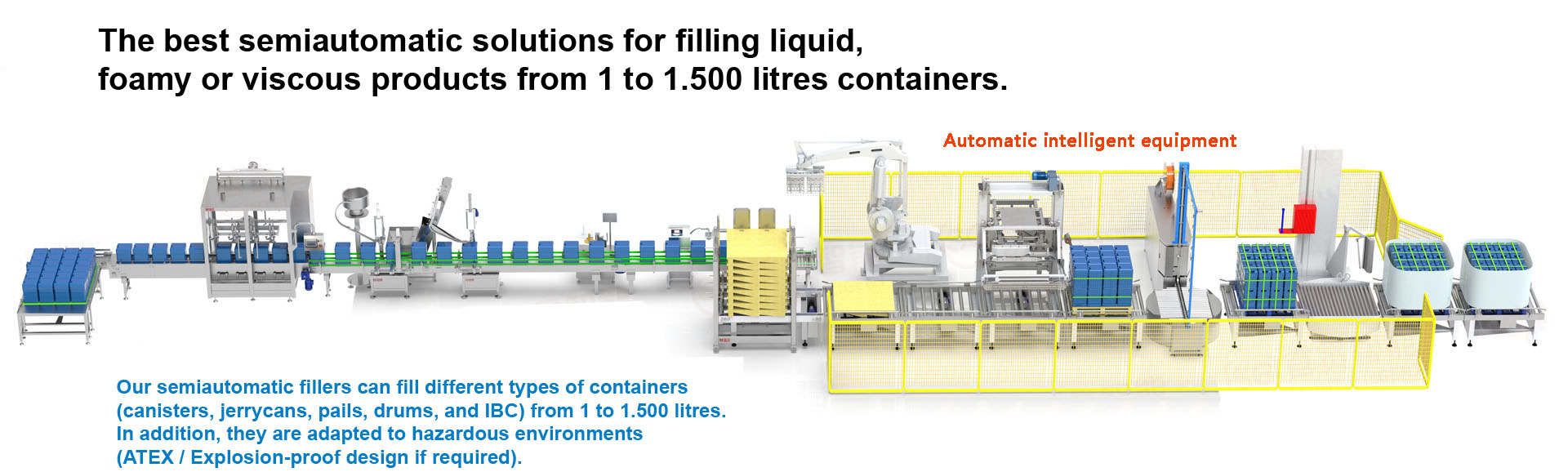

Our company specializes in production and packaging equipment for various materials including liquids, pastes, sauces, emulsions, and solidified liquids. We provide customized chemical filling systems, including liquid automatic fillers, paste fillers, automated filling production lines, and mixing tanks.

Technical Specifications:

Capacity: 60-200kg

Filling Weight: 200kg

Resolution: 50g

Filling Method: Semi-submerged two-stage filling

Installation: Floor-mounted

Filling Accuracy: ±0.1% F.S.

Speed: 38-42 barrels/hour (material flow rate must reach 200L/min)

Main body: Carbon steel with painted finish, material-contact parts made of SUS304 stainless steel

Semi-automatic liquid-level filling system

Interlocked with customer’s supply equipment

Pump-fed supply at the front of the machine

Explosion-proof requirement: Exde II BT4 Gb

Key Features:

? Easy installation – No complex debugging required

? Weighing-based filling – Adjustable from 25-280kg, user-friendly operation

? Precision control – Pneumatic ball valve regulates fast-to-slow filling for accuracy

? Adjustable filling head – Adaptable to different barrel heights

? Dual operation modes – Fully automatic or manual start for safety

? Corrosion-resistant materials – Standard 304 stainless steel & PTFE seals (optional PP/UPVC)

? Convenient barrel handling – Zinc-plated gravity rollers & adjustable support wheels

Operation Process:

Place an empty barrel on the weighing conveyor.

Manually open the lid and press the start button.

Align the filling nozzle (automatic or manual).

Fast filling switches to slow filling at preset weight.

Stops automatically at target weight.

Manually seal and move the filled barrel to the finished area.

Applications:

Ideal for petroleum, chemicals, pharmaceuticals, pesticides, and food processing industries.

Custom configurations available. Contact us for tailored solutions!