5L Filling Machine - High Automation & Strong Adaptability

5L Filling Machine - High Automation & Strong Adaptability - Detailed Product Specification

1. Product Overview

The 5L Filling Machine is a fully automatic, high-precision solution engineered for liquids, pastes, and particulates in 1-5L ranges. Designed for industries demanding flexibility and efficiency—such as food, beverage, chemical, and cosmetics—it combines ±0.3% filling accuracy with rapid changeovers. Compliant with CE, UL, FDA, and ISO 9001 standards, it excels in global markets requiring automation and versatility.

2. Core Features

2.1 High Automation

PLC & HMI Control:

Siemens S7-1200 PLC with 10.4” touchscreen for intuitive recipe management (stores 50+ products).

Real-time data logging and batch reporting for traceability.

Auto-Calibration:

Dynamic weighing mode adjusts for temperature/viscosity changes (1-10,000cPs).

Self-diagnostics with error codes and troubleshooting guides.

Integrated Conveyor System:

Auto-indexing with bottle detection (no-container/no-fill interlock).

Adjustable speed (0-30m/min) and lane width (50-400mm).

CIP/SIP Compatibility:

Automatic cleaning cycles with WFI (Water For Injection) and steam sterilization.

Clean-in-Place (CIP) mode reduces downtime by 40%.

2.2 Strong Adaptability

Wide Viscosity Range:

Handles water-thin liquids to heavy creams (1-10,000cPs).

Optional agitator for particulate-heavy suspensions.

Quick-Change Nozzles:

Tool-less disassembly in <3 minutes for 50-400mm containers.

Anti-drip design with silicone wiper seals.

Multi-Language Interface:

12 languages (EN/ES/FR/AR/ZH/RU/DE/PT/IT/JA/KO/VI) with video tutorials.

USB port for recipe import/export.

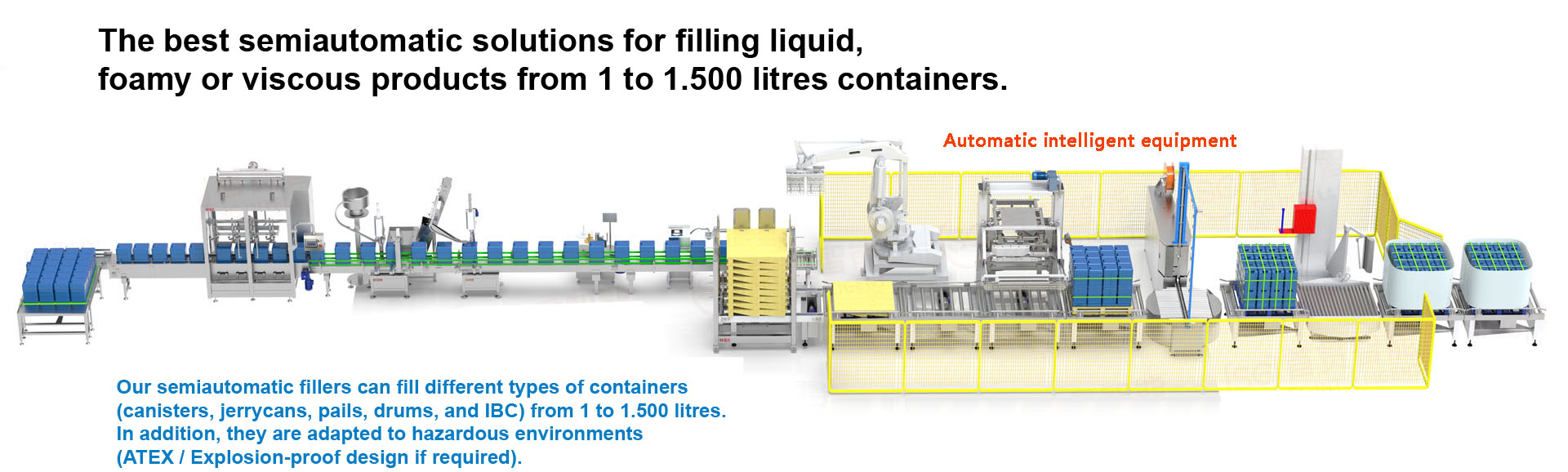

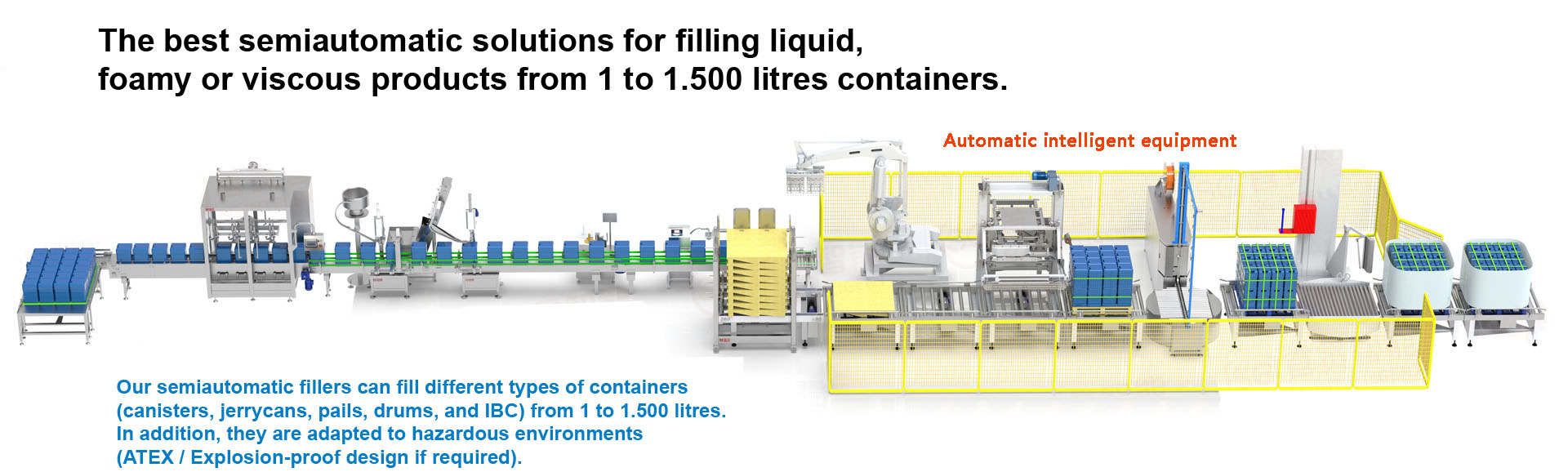

Explosion-Proof Option:

ATEX II 3G certification for flammable liquids (e.g., solvents, alcohols).

3. Technical Specifications

| Parameter | Details |

|---|---|

| Filling Capacity | 1-5L (adjustable), 20g incremental tuning |

| Accuracy | ±0.3% (static/dynamic weighing modes), OIML R61 certified |

| Speed | 600-1200 containers/hour (2.5L capacity, viscosity-dependent) |

| Power | 380V 50Hz, 2.2kW (explosion-proof variant available) |

| Air Supply | 0.6-0.8MPa, 0.6m3/min (NPT/G thread fittings) |

| Materials | 316L stainless steel (wetted parts), anodized aluminum frame |

| Control System | Siemens S7-1200 PLC + 10.4” HMI (multilingual) |

| Safety | CE/UL certified, emergency stop, SIL2 safety PLC, IP65 rated |

| Conveyor | 2m length, adjustable height (800-900mm), stainless steel rollers |

4. Technological Innovations

Adaptive Dosing Technology:

Servo-driven pump compensates for viscosity fluctuations in real-time.

Auto-tare function eliminates container weight variations.

Anti-Drip Nozzle:

Pneumatic shut-off with silicone wiper for foam-free filling.

Adjustable dive depth (0-300mm) for splash prevention.

Hygienic Design:

Crevice-free stainless steel construction with FDA-approved seals.

Sloped surfaces for drainage and easy cleaning.

Predictive Maintenance:

AI-driven alerts for component wear (85% accuracy).

Remote monitoring via IoT gateway (optional).

5. Applications

Food & Beverage:

Edible oils, sauces, honey, dairy products, and juice concentrates.

Cosmetics:

Lotions, shampoos, liquid foundations, and serums.

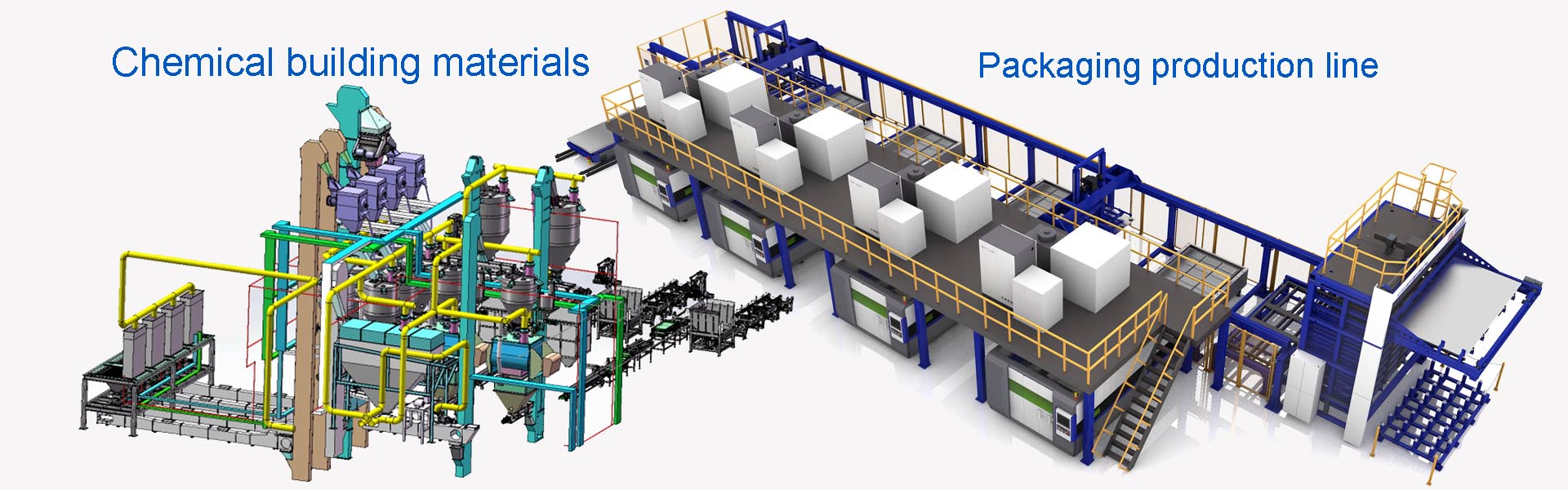

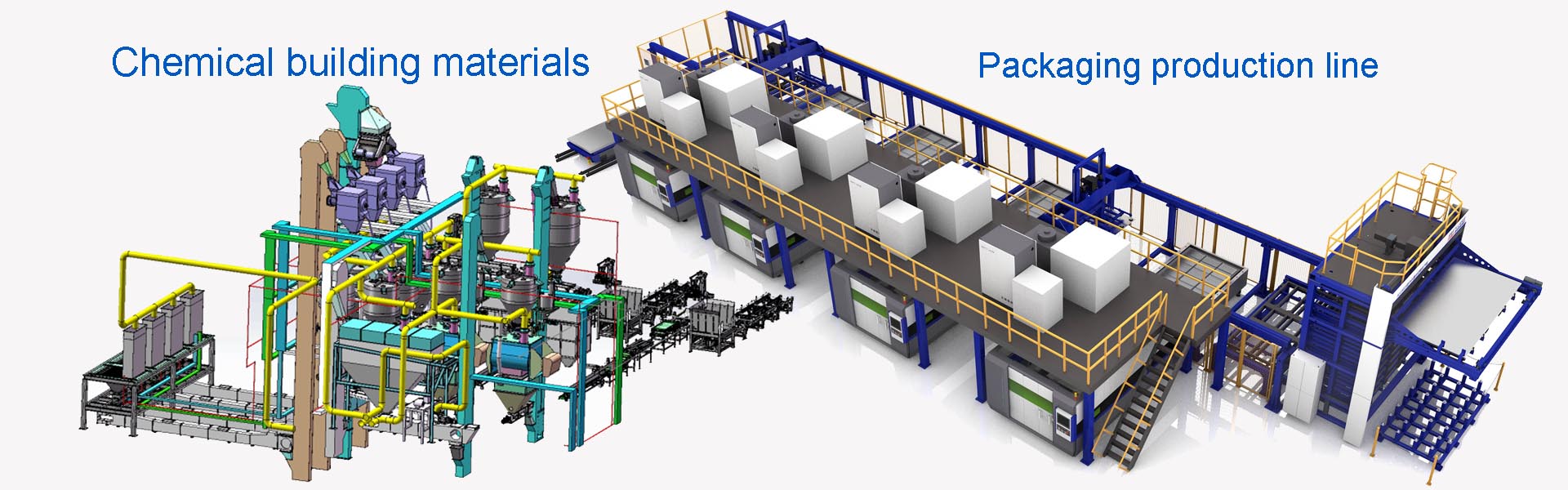

Chemicals:

Detergents, lubricants, agricultural chemicals, and adhesives.

Pharma:

Oral liquids, vaccines, sterile solutions, and ointments.

6. Global After-Sales Support

48-Hour Response:

Multilingual hotline in 8 languages (EN/ES/FR/AR/RU/ZH/DE/PT).

Video troubleshooting guides accessible via QR code.

On-Site Engineers:

150+ technicians worldwide, 72-hour deployment to major ports.

Annual maintenance contracts with priority support.

Spare Parts Logistics:

24-48 hour DHL delivery from regional hubs (Rotterdam, Dubai, Houston, Shanghai).

Critical kit: 1-year supply of seals, O-rings, and filters included.

Remote Diagnostics:

TeamViewer/VNC access for real-time troubleshooting.

Cloud-based performance analytics.

7. Export-Ready Compliance

Certifications:

CE, UL, FDA, ATEX, and ISO 9001 documentation provided.

Halal and Kosher compliance options.

Voltage Adaptation:

Pre-configured for 110V/220V and 50/60Hz.

Voltage stabilizer included for unstable grids.

Language Packs:

HMI interface and manuals in 12 languages.

Multilingual warning labels and safety signs.

8. Customization Options

Heated Hopper:

Temperature control up to 80°C for heat-sensitive materials.

Insulated stainless steel tank with digital thermostat.

Nitrogen Purge System:

For oxygen-sensitive products (e.g., pharmaceuticals, beverages).

Dust Cover:

IP65-rated enclosure for harsh environments.