2 Nozzles Semi Auto Ex-Proof Filling Machine for Cleaning Paint 2

2-Nozzle Semi-Automatic Ex-Proof Filling Machine for Cleaning Paint

Purpose-Built for Safe, Accurate, and Efficient Filling of Hazardous Liquids

Overview

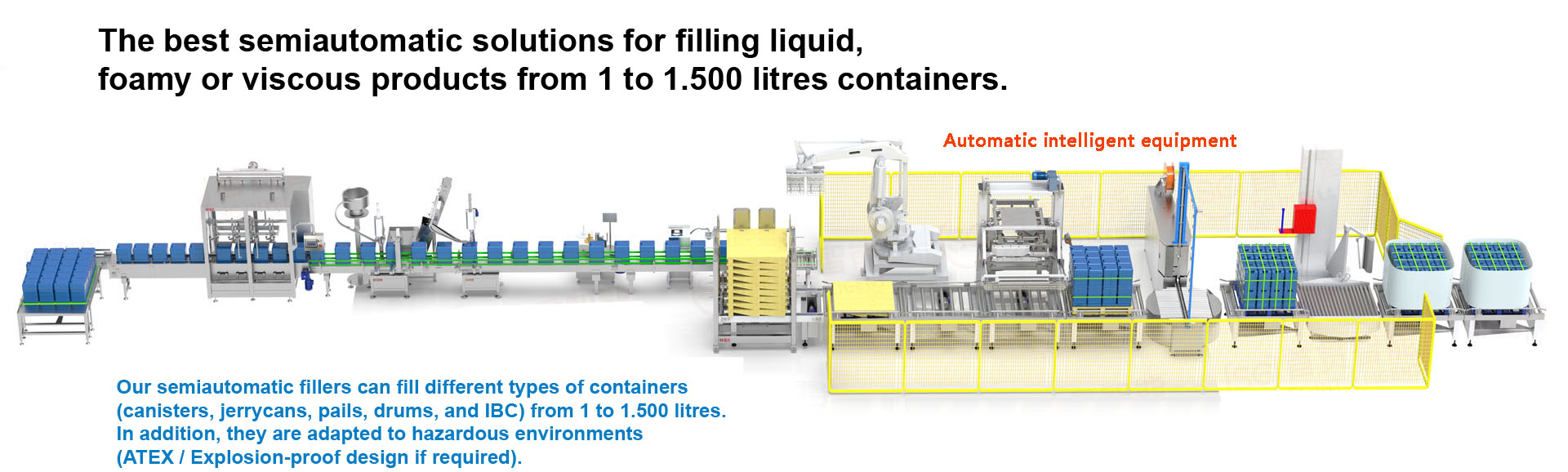

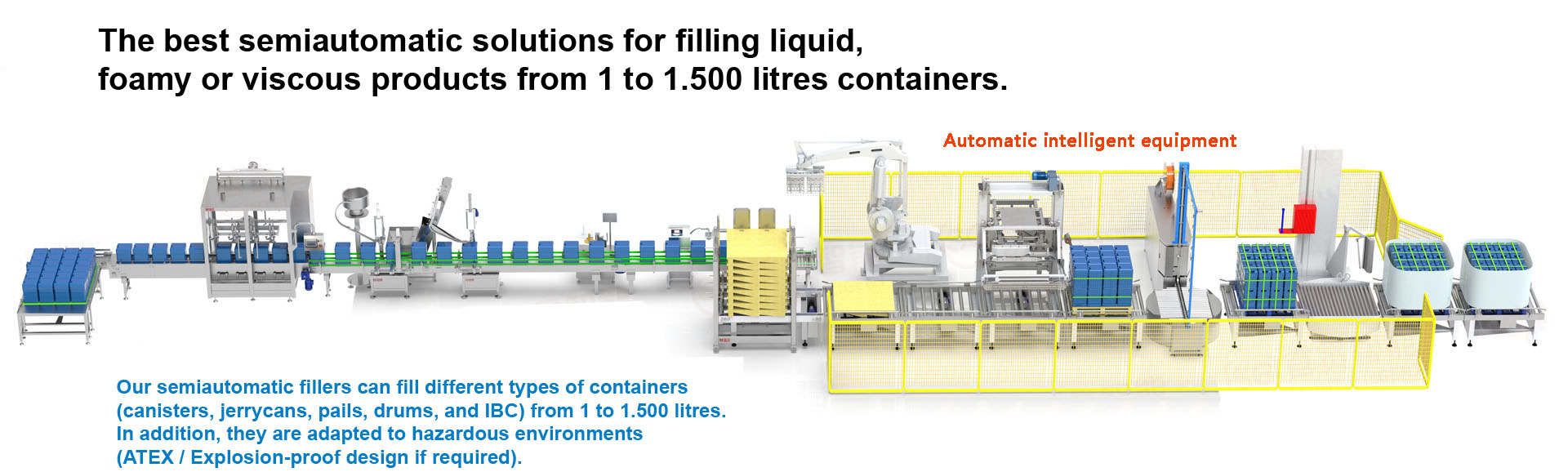

The 2-Nozzle Semi-Automatic Ex-Proof Filling Machine is designed for safe and precise filling of cleaning paints into containers (e.g., 5-gallon pails) in hazardous environments. It combines ATEX/IECEx explosion-proof certification with user-friendly operation, ensuring compliance with safety standards while maximizing productivity.

Key Features

1. Explosion-Proof Safety

ATEX/IECEx Compliance: Rated for Zone 1/21 and Zone 2/22 hazardous areas.

Spark-Resistant Electrical Components: Prevents ignition of flammable fumes.

Static Earthing System: Automated grounding of containers and nozzles to eliminate static discharge.

2. Dual-Nozzle Design

Two Independent Nozzles: Simultaneously fill two containers, doubling throughput.

Semi-Automatic Operation: Manual container placement with automatic filling and shutoff.

Adjustable Flow Rates: Customizable pump speeds (10–60 L/min) to handle viscous cleaning paints.

3. Precision Filling Technology

Weight-Based Control: High-accuracy load cells (±0.1%~0.2%) ensure exact fill volumes.

Dribble-Free Filling: Programmable stages (fast fill → slow fill → drip cutoff) prevent overfilling.

Nitrogen Purge (Optional): Inert gas purging to minimize foaming or contamination.

4. Corrosion Resistance & Durability

Stainless Steel Construction: 304/316L stainless steel frame and contact parts for chemical compatibility.

Chemical-Resistant Hoses & Seals: EPDM or Viton materials to withstand harsh chemicals.

Drip Tray & Containment: Stainless steel spill containment with emergency stop buttons.

5. User-Friendly Interface

Touchscreen HMI: Intuitive controls for recipe selection, real-time monitoring, and diagnostics.

Recipe Storage: Save up to 200+ product profiles for different paint formulations or container sizes.

Quick Changeover: Tool-free nozzle swaps and automated cleaning between batches.

6. Optional Upgrades

Automatic Capping System: Seal containers with tamper-evident caps.

Vision Inspection: Cameras to verify fill levels, cap alignment, or label placement.

Heated Nozzles: For high-viscosity paints requiring temperature control.

Applications

Cleaning Paints: Industrial degreasers, solvent-based cleaners, and heavy-duty coatings.

Other Applications: Chemicals, oils, adhesives, and other hazardous liquids.

Benefits

Safety First: ATEX certification and static earthing ensure compliance in explosive atmospheres.

High Throughput: Dual nozzles double productivity compared to single-nozzle machines.

Precision & Consistency: Weight-based filling eliminates overfilling or underfilling.

Corrosion Resistance: Stainless steel and chemical-resistant components for longevity.

Versatility: Suitable for various paint formulations and container sizes with customizable settings.

Why Choose This Machine?

This 2-Nozzle Semi-Automatic Ex-Proof Filling Machine offers a balance of safety, efficiency, and precision for filling cleaning paints in hazardous environments. Its ATEX certification, dual-nozzle design, and corrosion-resistant build make it the ideal choice for industrial applications requiring reliability and compliance.

Ready to optimize your filling process? Contact us for a tailored quote, demo, or site assessment!

Immediate Order:

Website: http://m.otgqoql.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Advanced 30L Explosion-Proof Emulsion and Paint Filling System[2025-04-28]

-

Small Industrial Filling Machine for Juice/Carbonated Beverages[2025-07-04]

-

Fully Automatic Ceramic Ink Filling and Capping Machine for 1-30L Bottles[2025-07-05]

-

Semi-Automatic Desktop Filling Machine for Filling 30L Resin Solvent/Lubricant[2025-04-01]