Real Stone Paint Explosion-proof Filling Machine with a Crown Lid, Easy to Operate with Touch Screen

Real Stone Paint Explosion-Proof Filling Machine with Crown Lid Sealing: Safe, Efficient, and User-Friendly

Overview

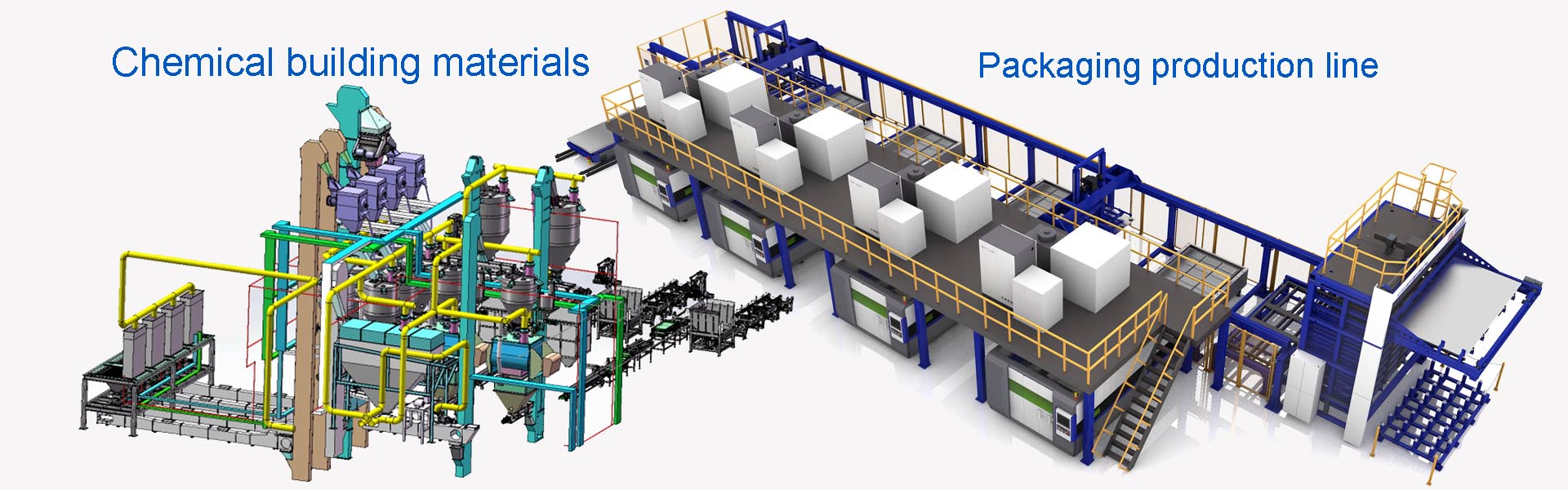

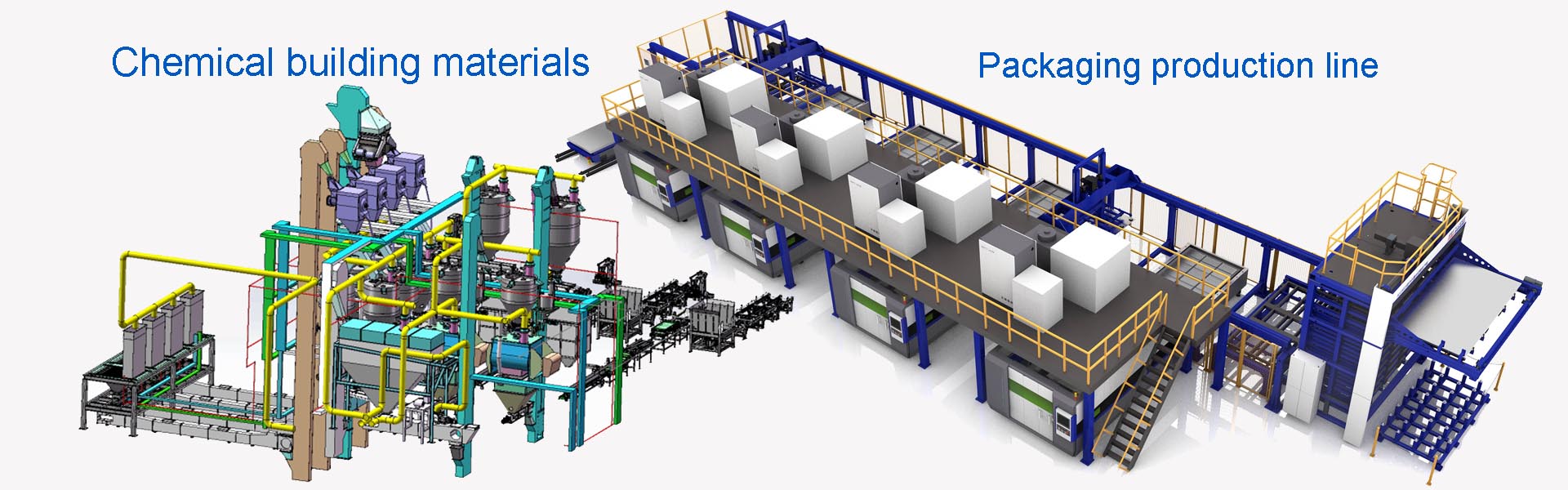

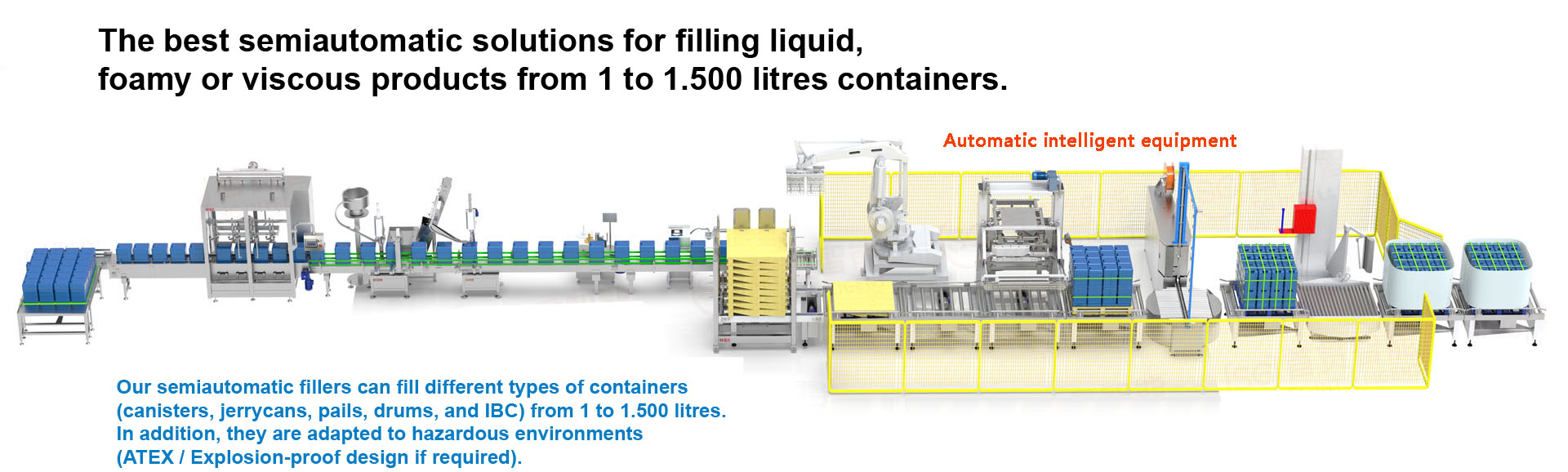

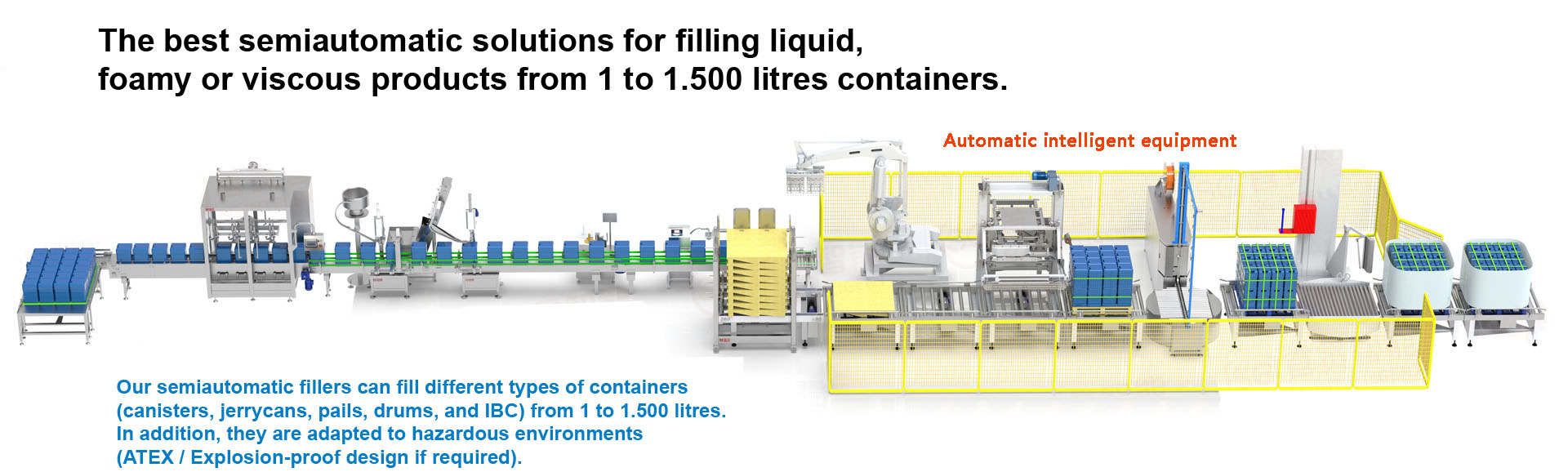

The Real Stone Paint Explosion-Proof Filing Machine is engineered for safe and precise filling of flammable or hazardous materials like real stone paints, solvents, and resins. Equipped with ATEX/IECEx explosion-proof certification, a crown lid sealing system, and an intuitive touchscreen interface, this machine combines safety, efficiency, and ease of operation for industrial applications. Perfect for 5-gallon containers, it ensures consistent fill weights, leak-proof sealing, and compliance with hazardous environment standards.

Key Features

Explosion-Proof Design

ATEX/IECEx Certified: Safe for use in Class I, Division 1 hazardous environments (flammable liquids/gases).

Spark-Resistant Components: Pneumatic systems, electrical enclosures, and stainless steel construction prevent ignition risks.

Nitrogen Blanketing Option: Inert gas purging to eliminate oxygen and reduce fire hazards.

Precision Weighing and Filling

Integrated Load Cells: ±0.5% accuracy for consistent fill weights.

Touchscreen Controls: Set target weights, monitor real-time data, and save recipes for different products.

High-Visibility Display: Clear status indicators for fill progress, weight, and error alerts.

Crown Lid Sealing System

Automated Lid Pressing: After filling, the machine seals crown lids tightly to prevent leaks and contamination.

Adjustable Torque Settings: Customize lid tightness for different container types and product viscosities.

Roll Feeder Compatibility: Accepts pre-cut or continuous roll lids for seamless operation.

User-Friendly Operation

Touchscreen Interface: Icon-based menus and pre-set recipes simplify setup and operation.

One-Button Start/Stop: Minimal training required; operators can start filling with a single press.

Multilingual Support: Available in multiple languages for global usability.

Safety and Compliance

Emergency Stop: Instant shutdown to protect operators and equipment.

IP65 Rating: Dust and water-resistant for washdown environments.

Corrosion-Resistant Materials: Stainless steel (304/316L) frame and hazardous area-rated components.

Durability and Low Maintenance

High-Flow Pneumatic Pump: Efficiently handles viscous products like real stone paint without clogging.

Wide-Bore Nozzles: Anti-clog design for thick, abrasive, or particulate-laden materials.

Sanitary Design: No dead legs or hard-to-clean areas; quick disassembly for maintenance.

Technical Specifications

Filling Range: 1–5 gallons per container (customizable for larger sizes).

Accuracy: ±0.5% of target weight.

Speed: Up to 120 containers/hour (depending on product viscosity and lid sealing).

Power Requirements: 220V/50Hz or 110V/60Hz (ATEX-compliant electrical system).

Materials: 304/316L stainless steel (corrosion-resistant and explosion-proof).

Nozzle Type: High-viscosity nozzle with anti-clog filter.

Lid Sealing: Crown lid press with adjustable torque (up to 30 RPM).

Display: Color touchscreen with multilingual support.

Operation Steps

Container Placement: Operator positions a 5-gallon container under the filling nozzle.

Recipe Selection: Touchscreen displays saved recipes; select the desired fill weight and lid settings.

Automatic Filling: Machine dispenses product while weighing in real time; stops automatically at target weight.

Lid Sealing: Crown lid is pressed and sealed with preset torque; container moves to exit.

Repeat: Move to the next container and repeat the process.

Applications

Real Stone Paints: Flammable or solvent-based coatings used in decorative concrete.

Hazardous Chemicals: Solvents, thinners, adhesives, and resins.

Industrial Coatings: Epoxy, polyurethane, and other viscous coatings.

Oil & Gas Products: Flammable fluids requiring explosion-proof handling.

Benefits

Safety First: Explosion-proof design and nitrogen blanketing ensure compliance in hazardous environments.

Precision and Reliability: Accurate weighing and leak-proof lid sealing minimize waste and rework.

Ease of Use: Touchscreen interface and one-button operation reduce training time and errors.

Versatility: Suitable for a wide range of viscous, flammable, or abrasive products.

Low Maintenance: Robust construction and sanitary design minimize downtime and upkeep costs.

Scalability: Easily upgradeable to fully automatic systems or integration with conveyors and cappers.

Why Choose This Machine?

The Real Stone Paint Explosion-Proof Filling Machine offers a comprehensive solution for safe and efficient filling of hazardous materials. Its combination of ATEX certification, touchscreen simplicity, and crown lid sealing ensures compliance, accuracy, and ease of operation. Whether you’re handling flammable paints, solvents, or viscous chemicals, this machine delivers the reliability and safety you need—backed by user-friendly technology and robust construction.

Contact us today to request a quote or schedule a demo!

-

Full Automatic Linear Piston Pump Detergent Filling Machine[2025-06-06]

-

Automatic Metering and Filling Machine for Filling 30L Plasticizer/Strong Acid/Petroleum[2025-07-05]

-

Multifunctional Filling Machine Is Suitable for Filling 200L Slurry/Emulsifiable Concentrate/Resin Drum[2025-04-29]

-

Semi-automatic Hopper Type Hardener Metal Pail Liquid Filling Machine[2025-04-28]