Semi-automatic Real Stone Paint Explosion-proof Filling Machine with Capping, Touch Screen, Preferential Price

Semi-Automatic Real Stone Paint Explosion-Proof Filling Machine with Capping, Touch Screen, and Preferential Price

Overview

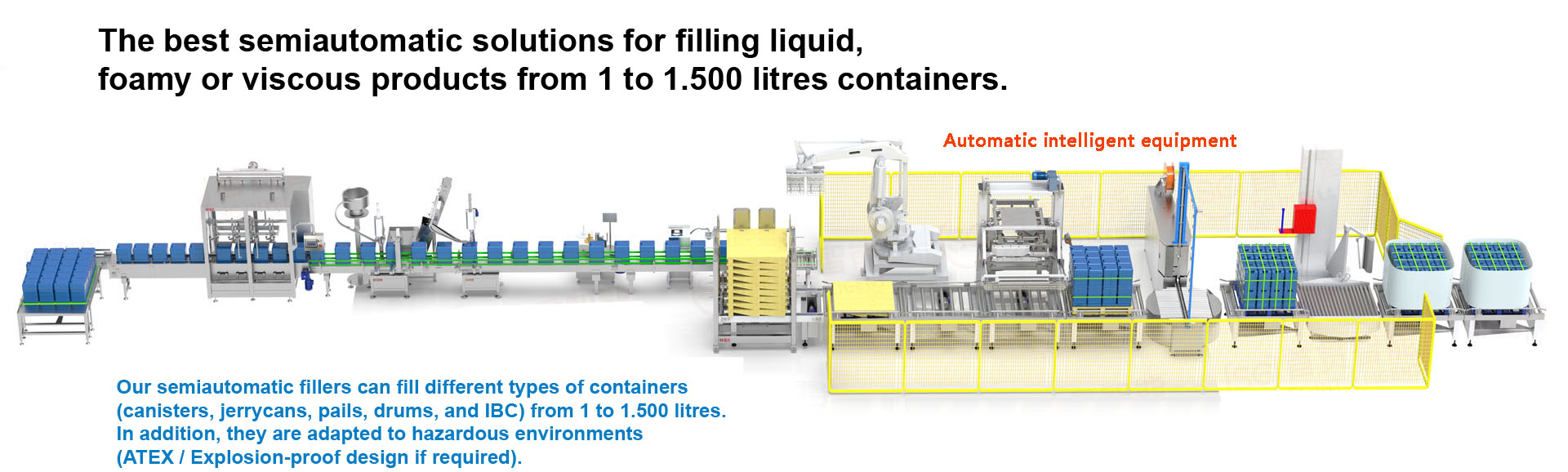

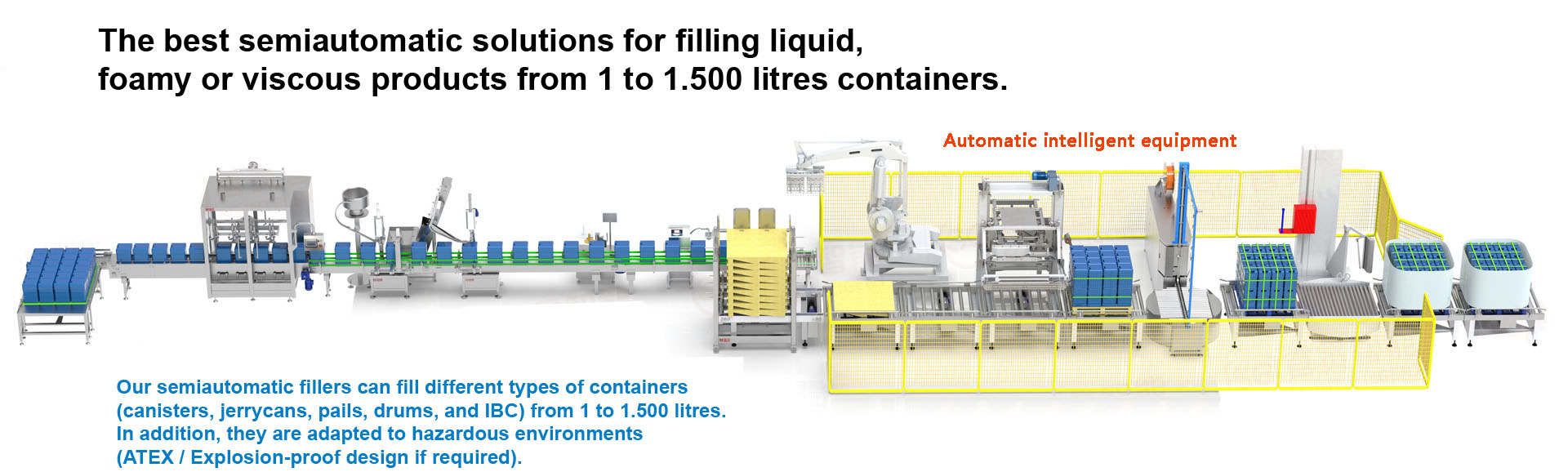

The semi-automatic explosion-proof filling machine is designed for safe and precise filling of real stone paints, solvents, and other hazardous liquids into 5-gallon pails or containers. It combines ATEX/IECEx certification for explosive atmospheres, a user-friendly touchscreen interface, and integrated capping—all at a competitive price point. This machine is ideal for small to medium-scale production requiring reliability, safety, and simplicity.

Key Features

Explosion-Proof Safety

ATEX/IECEx Certified: Suitable for Zone 1/21 hazardous environments (flammable liquids and gases).

Spark-Resistant Components: Pneumatics, motors, and electrical systems comply with explosion-proof standards.

Static Grounding: Automatic grounding of containers to prevent static sparks.

Touchscreen Control & Precision Filling

Intuitive HMI: Touchscreen interface for easy setup of fill volumes, speeds, and batch counting.

High-Accuracy Filling: ±0.5% accuracy with adjustable flow rates for viscous products like real stone paint.

Drip-Free Nozzles: Anti-clog design reduces mess and ensures clean operation.

Integrated Crown Lid Capping

Manual Capping Station: Semi-automatic crown lid sealing with preset torque control for airtight closure.

Optional Nitrogen Blanketing: Inert gas purging to minimize evaporation and oxidation (customizable).

Cost-Effective Design

Preferential Pricing: Affordable semi-automatic solution with no compromise on safety or performance.

Low Maintenance: Stainless steel construction and durable components reduce long-term costs.

Scalable Upgrades: Compatible with additional automation modules (e.g., conveyors, labeling) for future growth.

User-Friendly Operation

Simple Workflow: Operator loads container, selects parameters on the touchscreen, and initiates filling.

Compact Footprint: Space-saving design for small workshops or limited environments.

Multilingual Support: Touchscreen available in multiple languages for global usability.

Technical Specifications

Certification: ATEX/IECEx Zone 1/21 (hazardous liquids and gases).

Filling Range: 1–5 gallons per container (adjustable for smaller or larger volumes).

Speed: Up to 60 containers/hour (dependent on viscosity and operator熟練度).

Accuracy: ±0.5% of target weight.

Nozzle Type: High-viscosity, anti-clog nozzle with drip prevention.

Capping System: Manual crown lid press with torque control (optional servo upgrade).

Display: Touchscreen HMI with recipe storage and batch counter.

Power Requirements: 220V/50Hz or 110V/60Hz (energy-efficient).

Materials: 304 stainless steel (corrosion-resistant and durable).

Operation Steps

Container Placement: Operator positions the empty container under the filling nozzle.

Parameter Setup: Touchscreen selects fill volume, speed, and capping settings.

Automatic Filling: Machine fills to the target weight while preventing drips.

Manual Capping: Operator places the crown lid onto the container and engages the press for sealing.

Repeat: Continue for batch processing or switch recipes via the touchscreen.

Applications

Real Stone Paints: Viscous, solvent-based coatings for decorative concrete.

Hazardous Chemicals: Flammable solvents, thinners, adhesives, and resins.

Industrial Coatings: Epoxy, polyurethane, and other high-viscosity liquids.

Small to Medium Production Runs: Ideal for workshops, contract manufacturers, or startups.

Benefits

Safety: ATEX/IECEx certification ensures compliance with hazardous environment regulations.

Precision: High-accuracy filling minimizes overfill, saving materials and costs.

Affordability: Competitive pricing makes it accessible for small to medium businesses.

Ease of Use: Touchscreen controls and simple workflow reduce training requirements.

Scalability: Upgradeable to fully automatic systems or additional modules as needs grow.

Low Maintenance: Durable construction and spill-proof design minimize downtime.

Why Choose This Machine?

This semi-automatic explosion-proof filling machine offers a balance of safety, precision, and affordability for real stone paint manufacturers. Its ATEX certification, touchscreen convenience, and integrated capping make it a reliable choice for hazardous environments. Whether you’re a small workshop or growing business, this machine provides value-for-money performance without compromising on quality or safety.

Contact us today for a personalized quote or demo!

-

Full Automatic Honey Processing Machine and Filling Machine[2025-05-22]

-

Ink Solvent/Fertilizer Power Conveyor Filling Machine[2025-07-05]

-

Fully Automatic Multi-Station Filling Machine for Filling 1-25L Shampoo/Cream/Olive Oil[2025-07-03]

-

Fully Automatic Multi-Station Filling Machine Is Suitable for Glue/Resin/Emulsion Filling[2025-05-07]