OilDrum Pro OD-3000 Series

Automatic Oil Drum Filling Machine

Precision. Safety. Industrial Reliability.

Technical Specifications

Parameter | OD-3100 (Standard) | OD-3200X (ATEX) | OD-3300H (High-Visc) |

|---|

Capacity | 20-220L (±0.2%) | 20-220L (±0.3%) | 20-220L (±0.25%) |

Throughput | 35 drums/hour | 30 drums/hour | 32 drums/hour |

Accuracy | ±0.2% gravimetric | ±0.3% | ±0.25% |

Viscosity Range | 10-100,000 cP | 50-80,000 cP | 500-500,000 cP |

Filling Technology | Coriolis Mass Flow | ATEX Gear Pump | Heated Screw Conveyor |

Material Contact | 316L SS + PTFE | Hastelloy C276 | Hardox 400 + PEEK Lining |

Explosion Protection | N/A | Zone 1 (IIB T4) | N/A |

Static Control | <10? Ω (NFPA 77) | <10? Ω | <10? Ω |

Overfill Prevention | Radar + Weight Redundancy | Same + SIL-2 | Triple Sensor System |

Power | 380V/50Hz, 7.5kW | 24VDC Ex ia | 380V/50Hz, 9.2kW |

N? Consumption | 40 L/min | 50 L/min | 45 L/min |

Cycle Time | 1.7 min/drum | 2.0 min/drum | 1.8 min/drum |

Footprint (L×W×H) | 3500×1800×2500mm | 3800×2000×2700mm | 3600×1900×2600mm |

Core Innovations

1. TripleShield? Safety System

Certified Protection:

ATEX Zone 1 Compliance (IECEx IEC 60079)

Spill Containment: 304 SS drip tray (50L capacity)

Emergency Shutdown: <0.3s response (SIL-2)

2. Viscosity-Adaptive Filling

Oil Type | Technology | Performance |

|---|

Light Hydraulic | High-Flow Mode (200 L/min) | ±0.15% accuracy |

Gear Oil ISO 680 | Heated Path (60°C±1°C) | Viscosity stability ±2% |

Grease NLGI 2 | Pulsed Piston Filling | Zero air inclusion |

Industry Applications

Lubricant Manufacturing

Feature | Specification |

|---|

API Certification | Auto-viscosity compensation |

Additive Dosing | 8-port system (±0.5%) |

MIL-PRF Compliance | Military spec filling protocols |

Fuel & Petrochemicals

Flash point monitoring (>38°C)

Conductive filters (<10? Ω)

Reid vapor pressure compensation

Transformer & Dielectric Oils

Parameter | Solution |

|---|

Moisture Control | Dehumidified N? blanket |

Particulate | 5μm final filtration |

Dielectric Loss | Filling under vacuum (-0.8 bar) |

Smart Control System

10" HMI with PetroOS?

AI-Driven Safety:

Performance Data

Metric | Manual Filling | OD-3100 | Improvement |

|---|

Output | 12 drums/hour | 35 drums/hour | ↑192% |

Oil Loss | 2.8% | <0.1% | ↓96% |

VOC Emission | 450 ppm | <5 ppm | ↓99% |

Labor Cost | 3 operators | 0.5 FTE | ↓83% |

Certifications

? ATEX 2014/34/EU (OD-3200X)

? API 682 Seal Standard

? ISO 80079-36 Explosive Atmospheres

? OSHA 1910.106 Compliance

? CE EN 60204-1

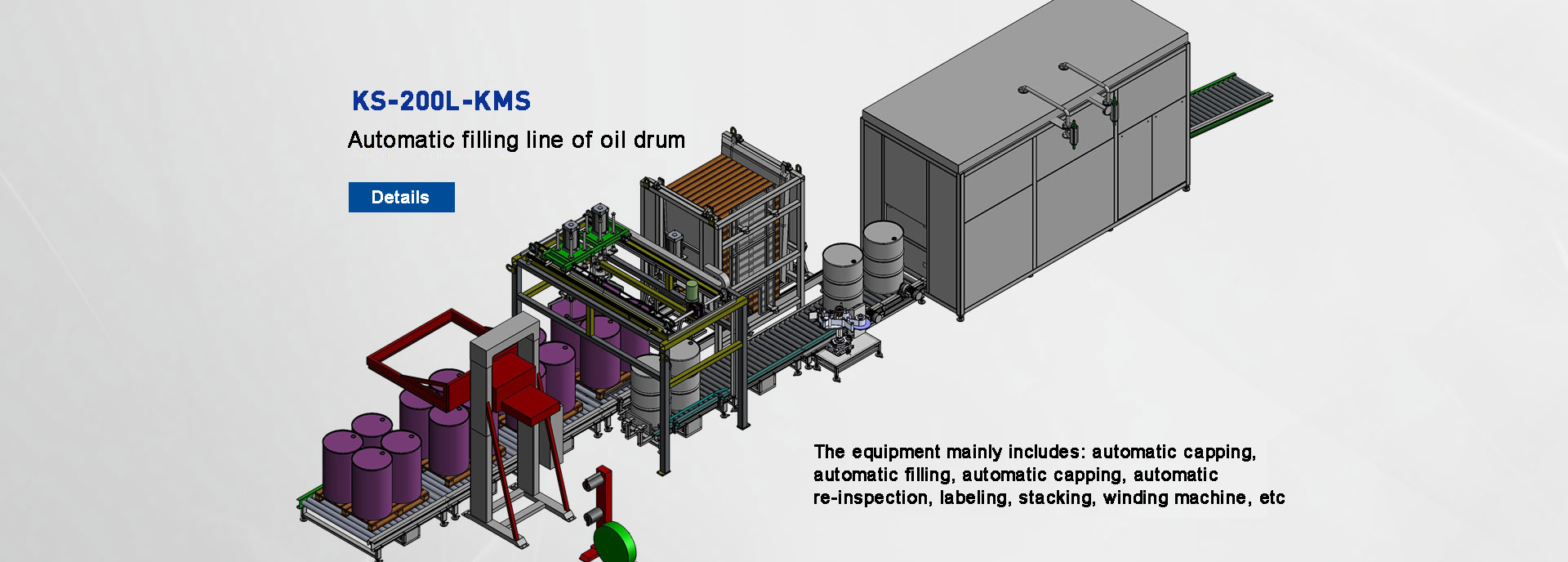

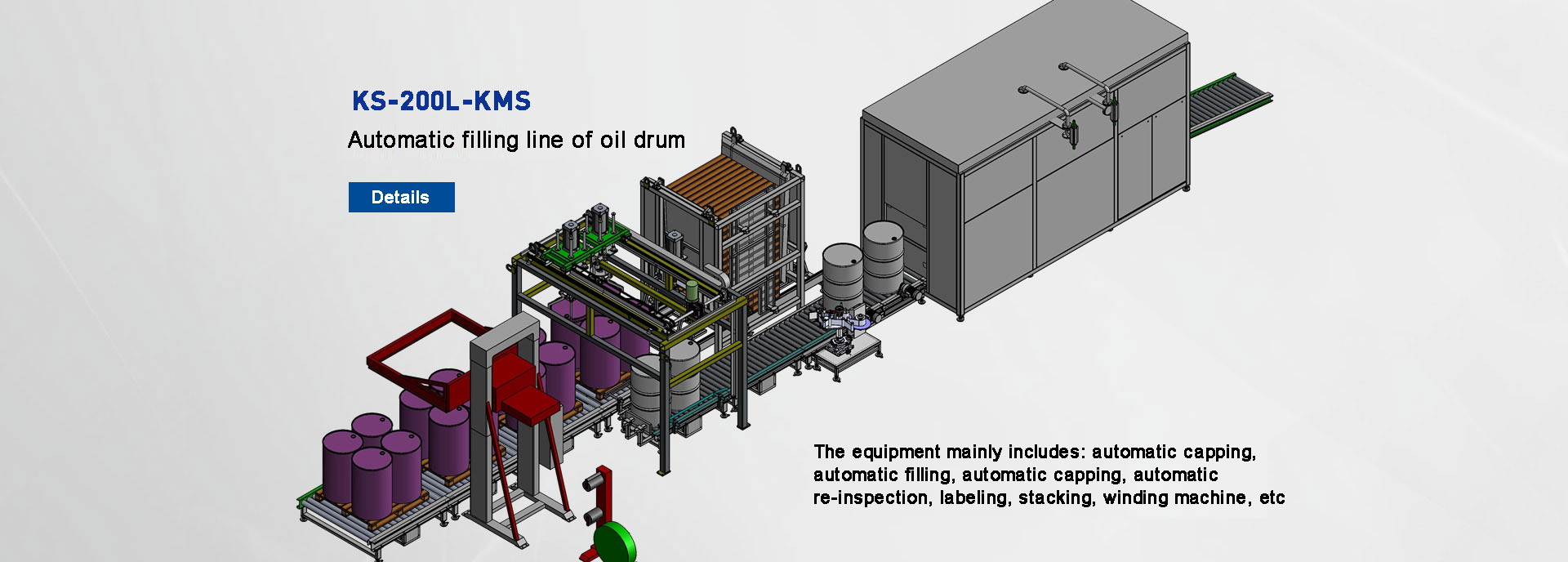

Operational Workflow

1. AGV Drum Loading → 2. Laser Bung Alignment →

3. N? Purging (O?<0.5%) → 4. Mass Flow Filling (±0.2%) →

5. Auto Torque Sealing → 6. Vapor Recovery →

7. Palletizing

Cycle Time: 1.7 minutes/drum

SEO Optimization

Element | Content |

|---|

Title (60 chars) | Automatic Oil Drum Filler | 35 Drums/H | ±0.2% | ATEX | Shanghai Guangzhi |

Description (150 chars) | Industrial oil drum filling: 35 drums/hour, ±0.2% accuracy. ATEX Zone 1 certified. N? inerting & VOC capture. Free quote! |

Core Keywords | 1. Automatic Drum Filling Machine

2. Oil Drum Packing System

3. ATEX Drum Filler

4. High-Speed Lubricant Packaging |

Tags | Lubricant Manufacturing, Fuel Packaging, Transformer Oil, Explosion Proof Filling, Industrial Oils

|

Service Package

Service | Standard | Premium |

|---|

Installation | 5-day plant commissioning | Turnkey integration |

Remote Monitoring | 24/7 IIoT diagnostics | AR-guided troubleshooting |

Spare Parts | 48h global delivery | On-site critical inventory |

Training | 3-day operator certification | Custom ERP integration |