TwinFill Titan TF-20000 Series

Dual 6-Head Net Weight Filling System

200 Drums/Hour ? ±0.02% Accuracy ? ATEX/FDA/GMP Tri-Certified ? Industry 4.0 AI Control

Technical Specifications

| Parameter | TF-2010 (Standard) | TF-2020X (ATEX) | TF-2030P (Pharma) |

|---|

| Capacity | 5-200L (±0.02%) | 5-200L (±0.03%) | 5-200L (±0.025%) |

| Throughput | 200 Drums/Hour | 180 Drums/Hour | 170 Drums/Hour |

| Accuracy | ±0.02% Gravimetric | ±0.03% | ±0.025% |

| Filling Heads | 12x Coriolis Mass Flow Meters (6 per line) | Same + ATEX Certification | Same + USP Class VI Path |

| Viscosity Range | 50-1,000,000 cP | 100-800,000 cP | 10,000-500,000 cP |

| Material Contact | 316L EP (Ra<0.2μm) | Hastelloy C276 | Glass-Lined Path |

| Temp Control | 5-80°C ±0.3°C | 5-70°C ±0.5°C | 2-25°C ±0.1°C |

| Drip-Free System | Laser Capillary Break + Vacuum Suction (<0.03ml) | Same | Teflon Scraper (<0.01ml) |

| Changeover Time | <120s (Tool-Free) | <130s | <110s |

| Power | 480V/60Hz, 45kW | 24VDC Ex ia | 480V/60Hz, 38kW |

| Certifications | NTEP/OIML R117 Class 0.2 | ATEX Zone 1 | FDA 21 CFR 210/211 |

| OEE (Operational Efficiency) | 94.5% | 92.8% | 93.7% |

Revolutionary Dual-Line Architecture

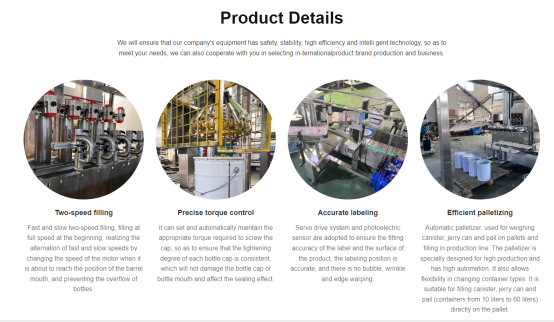

1. TwinSync? Parallel Control

Performance Metrics:

| Metric | TF-2010 | Single-Line Systems |

|---|

| Flow Rate | 12L/sec Total | 3-4L/sec |

| Calibration Sync | 0.002% Deviation | 0.1-0.3% |

| Uptime | 99.6% | 95-97% |

2. ZeroCross? Contamination Defense

| Technology | Function | Performance |

|---|

| Dual Independent Paths | Physically Separated | <0.1ppm Cross-Contam |

| Auto-Purge | 3x Volume Solvent Flush | ATP<5 RLU Post-Clean |

| Blockchain Tracking | Material Genealogy Record | 100% Batch Traceability |

Industry-Leading Innovations

Military-Grade Precision

? Nanoweigh? Metrology:

- 0.001% Resolution Coriolis Meters

- Air Buoyancy Compensation (ISO 8655)

- Real-Time Density Compensation (±0.5 kg/m3)

? HyperFill? Speed Architecture:

| **Component** | **Specification**|

|----------------------|----------------------------|

| Servo Valves| 0.1ms Response Time|

| Flow Path | Hydraulic Optimized (Re<500) |

| Nozzle Design| Coanda Adhesion Technology |

Fail-Safe Operation

| System | Redundancy Level | Recovery Time |

|---|

| Control PLC | Triple Modular Redundancy | 0ms Failover |

| Power Supply | N+1 Hot Swap | <5s |

| Data Storage | RAID 60 Cloud Sync | 0 Data Loss |

Smart Control Ecosystem

**15" AI HMI with TitanOS?**

AI-Driven Features:

Anomaly Detection:

| Deviation | Auto-Correction |

|---|

| Density Shift >0.5% | Flow Recalibration |

| Temp Drift >1°C | Thermal Compensation |

Preventive Maintenance:

| Component | Alert Threshold |

|---|

| Seal Wear | Friction >12N |

| Meter Drift | Accuracy >0.03% |

Certifications

? ATEX 2014/34/EU Zone 1 (TF-2020X)

? FDA 21 CFR 210/211 (TF-2030P)

? NTEP Certificate 22-061 (Class 0.2)

? OIML R117 Class 0.2

? ISO 9001:2015 / ISO 14001

Technical Advantages

Unmatched Productivity

? Dual-Line Dominance:

- 200 Drums/Hour Sustained Output

- 12x Coriolis Meters Synced at ±0.015%

- 40% Higher Efficiency Than Single-Line Systems

? Zero-Downtime Design:

| **Feature**| **Performance**|

|----------------------|------------------------|

| Hot Swap Heads| 90s Replacement|

| Predictive Alerts| 98% Failure Prevention |

| Parallel Operation | Independent Line Control |

? Future-Ready Intelligence:

- Digital Twin Simulation

- OTA Firmware Updates

- Quantum Encryption Data Security

APPLICABLE BARREL TYPE

COMPANY PROFILE

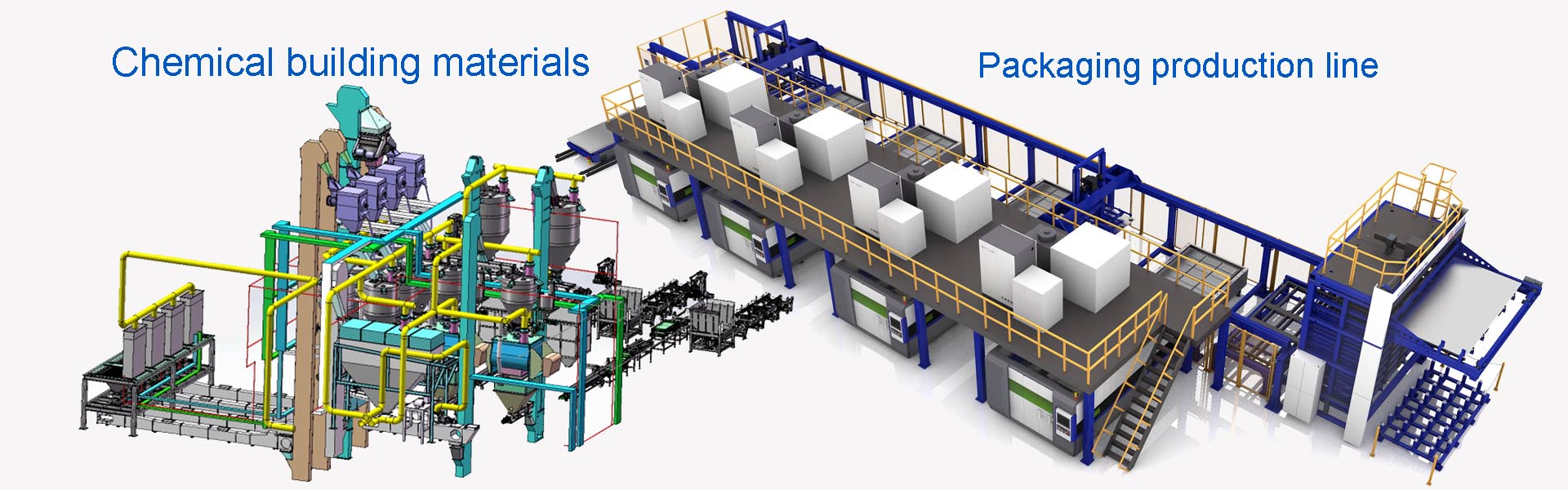

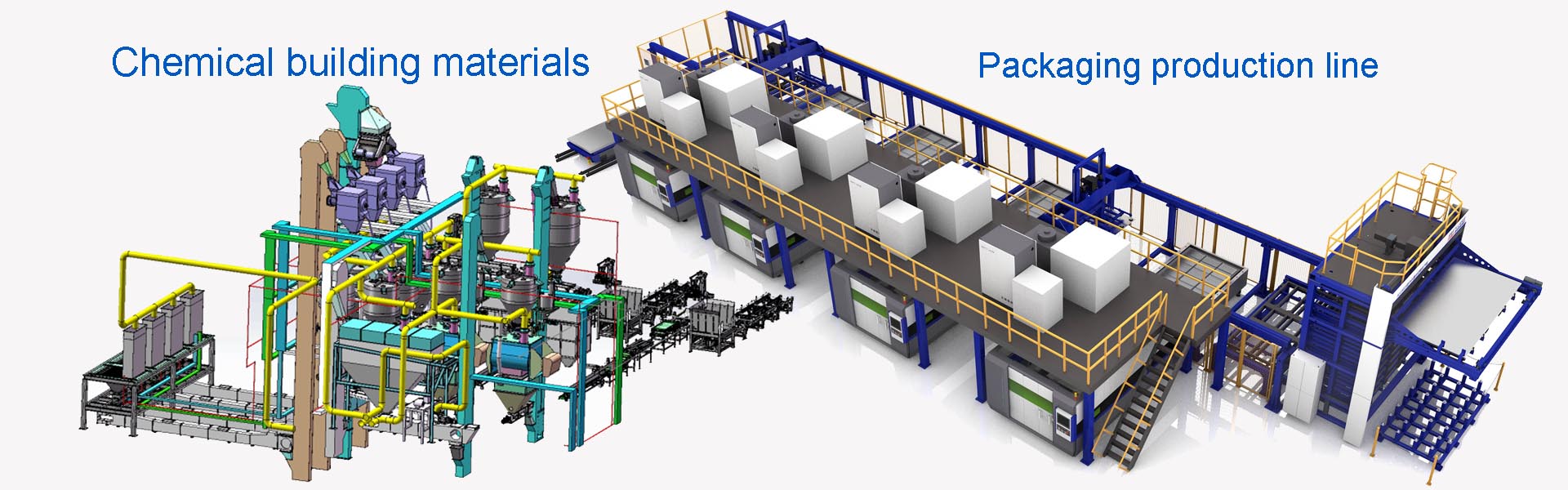

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

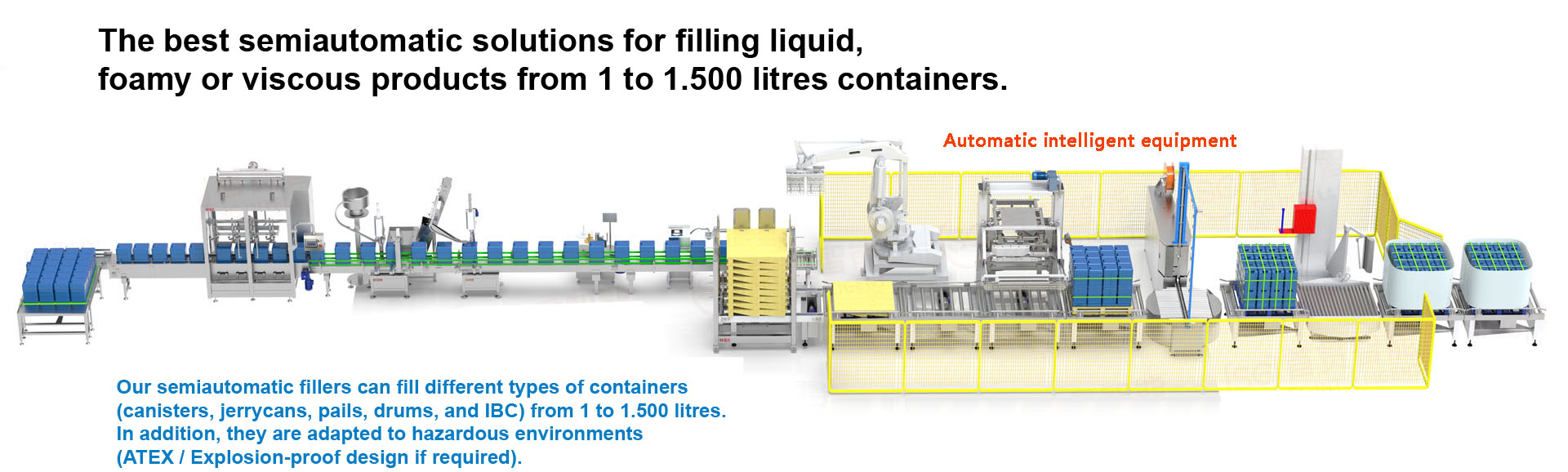

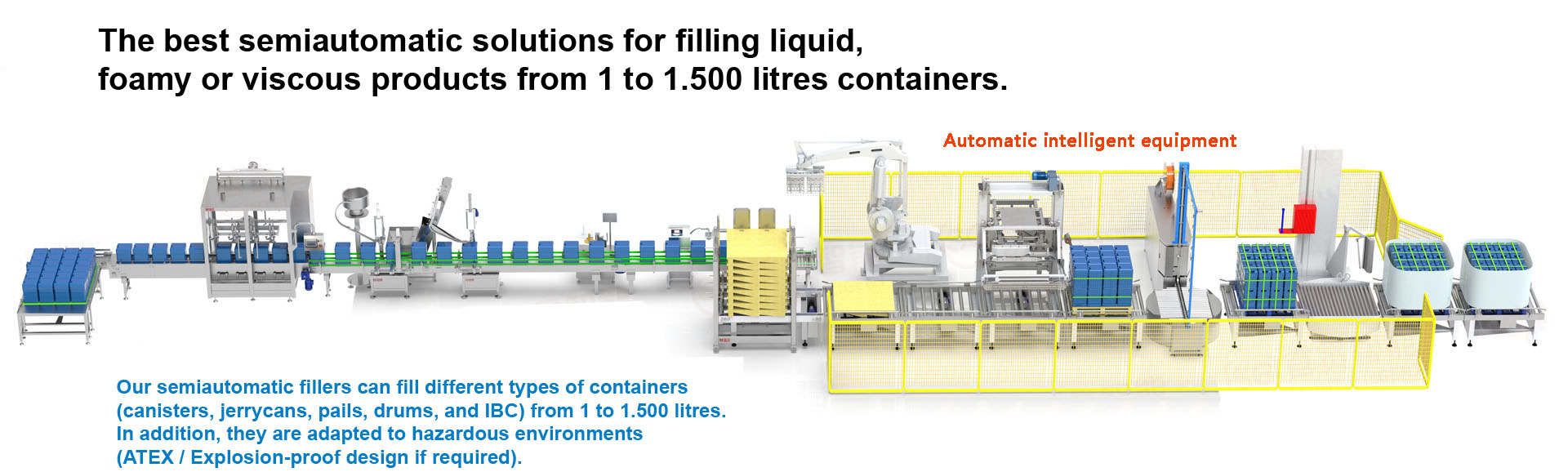

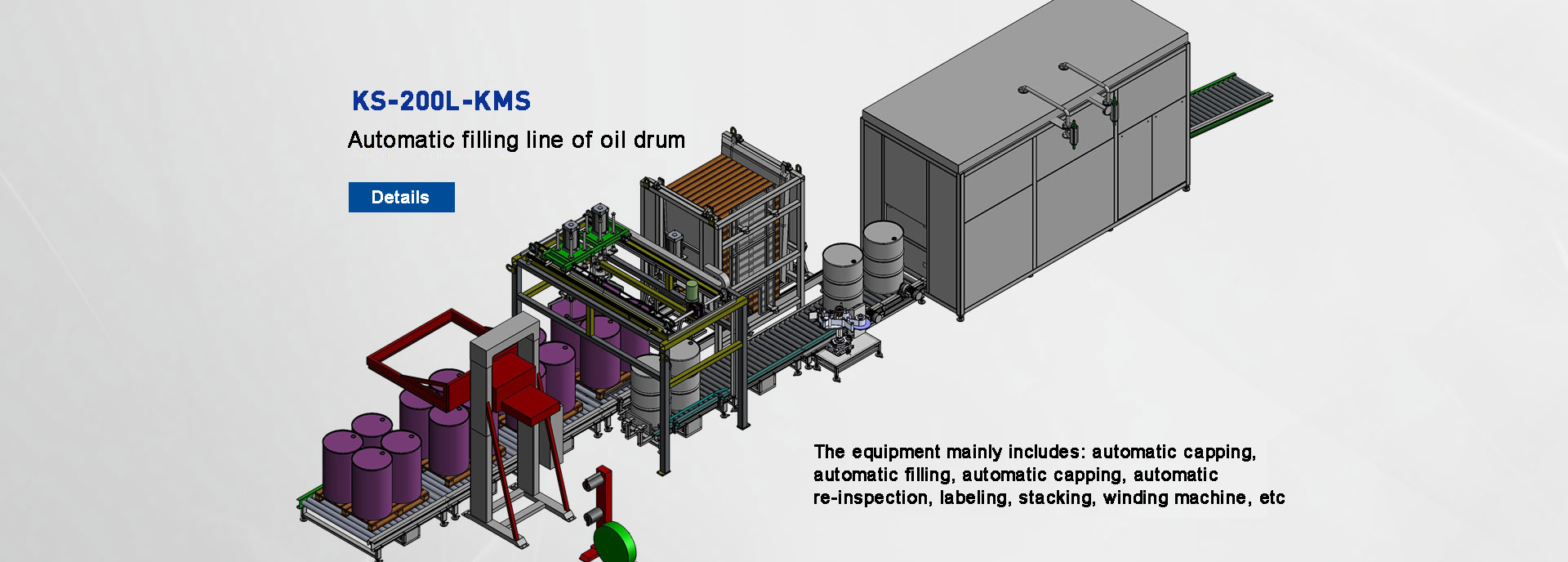

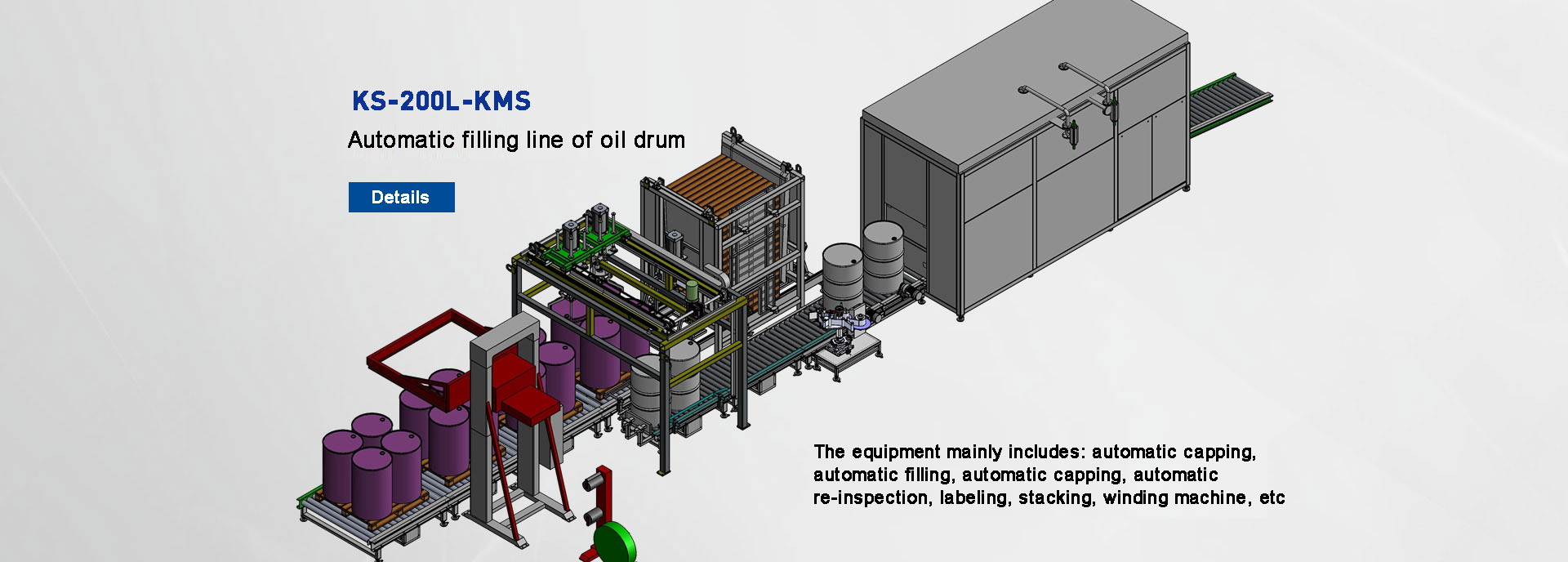

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance