BevFill Pro BF-9000 Series

High-Speed Beverage Filling Line

36,000 BPH ? ±0.5% Accuracy ? Aseptic/Carbonation Ready ? 90s Changeover

Technical Specifications

| Parameter | BF-9100 (CSD) | BF-9200A (Aseptic) | BF-9300J (Juice) |

|---|

| Capacity | 150ml-2L (±0.5%) | 150ml-2L (±0.3%) | 150ml-2L (±0.4%) |

| Throughput | 36,000 BPH | 32,000 BPH | 30,000 BPH |

| Accuracy | ±0.5% Volumetric | ±0.3% Gravimetric | ±0.4% Gravimetric |

| Product Types | Carbonated ? Still ? Energy Drinks | Juices ? Dairy ? Plant-Based | Hot Fill ? Cold Press |

| Filling Technology | Isobaric Counter-Pressure | Aseptic Gravity Filler | Vacuum-Assisted Gravity |

| Carbonation Control | ±0.1g/L CO? | N/A | N/A |

| Temp Range | 1-4°C ±0.5°C | Ambient to 30°C | 85-92°C ±0.3°C |

| Material Contact | 316L EP (Ra<0.4μm) | 316L EP (Ra<0.2μm) | Ceramic-Coated Path |

| Bottle Compatibility | PET/Glass/Cans<br>?50-100mm | Same + Bag-in-Box | Same + Tetra Pak |

| Capping/Crimping | ROPP ? Screw Cap ? Can Seam | Induction Sealing | Tamper-Evident Cap |

| Cleanability | CIP 25-min Cycle | SIP/CIP 30-min Cycle | CIP 20-min Cycle |

| Power | 480V/60Hz, 125kW | 480V/60Hz, 110kW | 480V/60Hz, 100kW |

| Water Consumption | 1.5L/1000 Bottles | 1.2L/1000 Bottles | 1.8L/1000 Bottles |

| Certifications | FDA 21 CFR 110 ? ISO 22000 | SQF Level 3 ? EHEDG EL Class I | HACCP ? Kosher/Halal |

Core Innovations

1. CarboLock? Precision Carbonation

Performance Metrics:

| Drink Type | CO? Level | Foam Height | Fill Accuracy |

|---|

| Cola | 5.0g/L | <2mm | ±0.4% |

| Sparkling Water | 8.0g/L | <1mm | ±0.3% |

| Beer | 2.5g/L | <3mm | ±0.6% |

2. UltraClean? Aseptic System

| Technology | Function | Performance |

|---|

| H?O? Sterilization | Vapor Phase (35% w/w) | 6-log Micro Reduction |

| Laminar Flow Hood | ISO Class 5 Environment | <0.1 CFU/100ml |

| Flash Pasteurization | 72°C/15s + Instant Cooling | 99.999% Pathogen Kill |

Beverage-Specific Engineering

Carbonated Soft Drinks (CSD)

| Feature | Technology |

|---|

| Foam Control | Double Pre-Surge Chamber |

| Oxygen Scavenging | N? Dosing (O?<0.1ppm) |

| Sugar Crystallization | Ultrasonic Agitation |

Juices & Dairy

Vitamin Preservation:

| Component | Specification |

|---|

| Amber UV Hood | Light Oxidation Barrier |

| Deaeration System | -0.9bar Vacuum (O?<0.3%) |

Pulp Integrity:

Hot-Fill Applications

| Component | Function |

|---|

| 92°C Path Heating | Microbe Elimination |

| Invert Cooling | 92°C→30°C in 8s (Bottle Integrity) |

| Vacuum Compensation | -0.7bar Residual Vacuum |

Smart Control Ecosystem

**15" HMI with BevOS?**

AI-Driven Features:

Quality Sentinel:

| Parameter | Action |

|---|

| pH Shift >0.2 | Acid Dosing Adjustment |

| CO? Drift >0.2g/L | Pressure Recalibration |

Efficiency Optimizer:

| Metric | Real-Time Control |

|---|

| O? Ingress | <0.1ppm Auto-Seal |

| Energy Consumption | 0.1kWh/Liter |

Line Configuration

Integrated Production Line:

1. Air Conveyor Infeed → 2. UV Sterilization Tunnel →

3. Isobaric Filling (±0.5%) → 4. Steam Flush Capping →

5. Laser Coding → 6. Vision Inspection →

7. PackBot? Robotic Palletizing

Key Modules:

| Module | BF-9100 Spec |

|---|

| Rinser | 3-Stage Ionized Water |

| Filler | 120 Valves Rotary Filler |

| Capper | 80 Heads Servo Torque Control (±0.5 N·m) |

| Pasteurizer | Tunnel 72°C/15s (30m Length) |

| PackBot | 60 Cases/Minute |

Certifications

? FDA 21 CFR 110/117

? ISO 22000:2018

? SQF Level 3 (BF-9200A)

? EHEDG EL Class I

? CE EN 1672-2

Technical Advantages

Beverage-Perfect Precision:

? Carbonation Mastery:

| **Technology**| **Performance**|

|-------------------------|------------------------|

| Isobaric Filling | ±0.1g/L CO?|

| Double Pre-Surge | <2mm Foam Height |

| Laser CO? Sensor | 0.01g/L Resolution|

? Aseptic Assurance:

1. H?O? Vapor Sterilization (6-log)

2. Laminar ISO Class 5 Hood

3. Real-Time Microbiological Monitoring

? Sustainability Edge:

- 40% Water Reduction (Closed-Loop Rinse)

- 0.1kWh/Liter Energy Consumption

- 0.5% Product Loss (Industry Lowest)

Models & Configurations

| Model | Target Product | Key Feature | ROI Period |

|---|

| BF-9100 | Carbonated Drinks | Isobaric CO? Control | 14 Months |

| BF-9200A | UHT Milk/Juices | Aseptic SIP Validation | 18 Months |

| BF-9300J | Hot-Fill Juices | 92°C Path + Vacuum Cooling | 16 Months |

Performance Validation

PepsiCo Bottling Plant Report:

*"After 12 months using BF-9100:

Output: 24,000 → 36,000 BPH (+50%)

CO? Consistency: ±0.5g/L → ±0.08g/L

Annual Savings: $1.2M (Product + Energy)

ROI: 13 months"*

APPLICABLE BARREL TYPE

COMPANY PROFILE

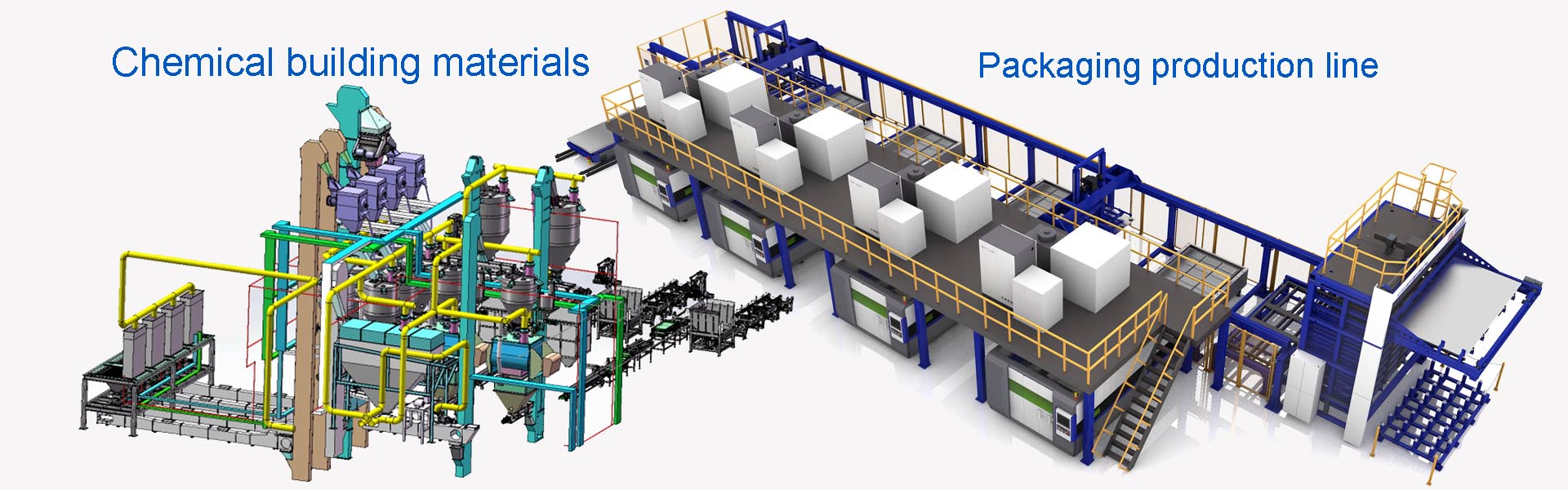

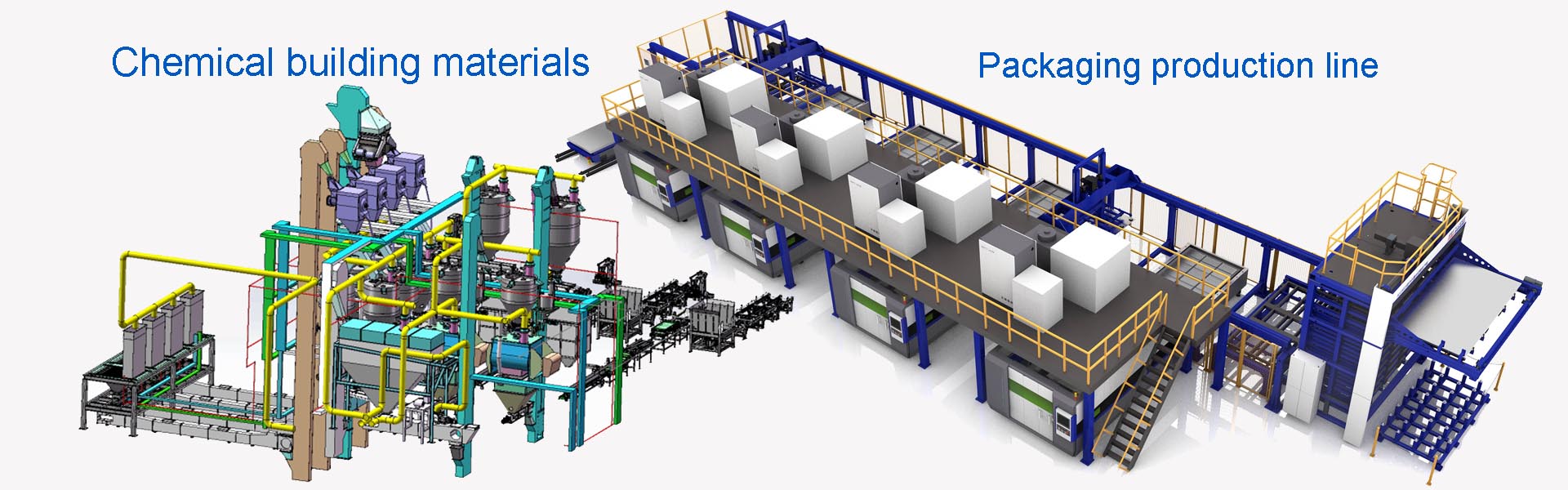

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

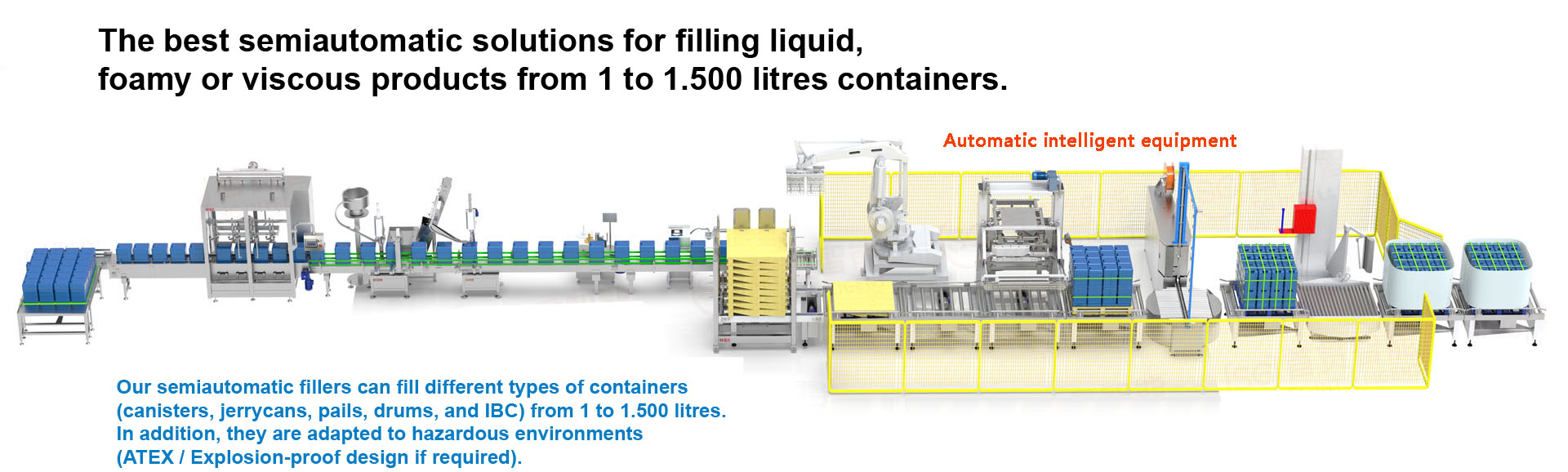

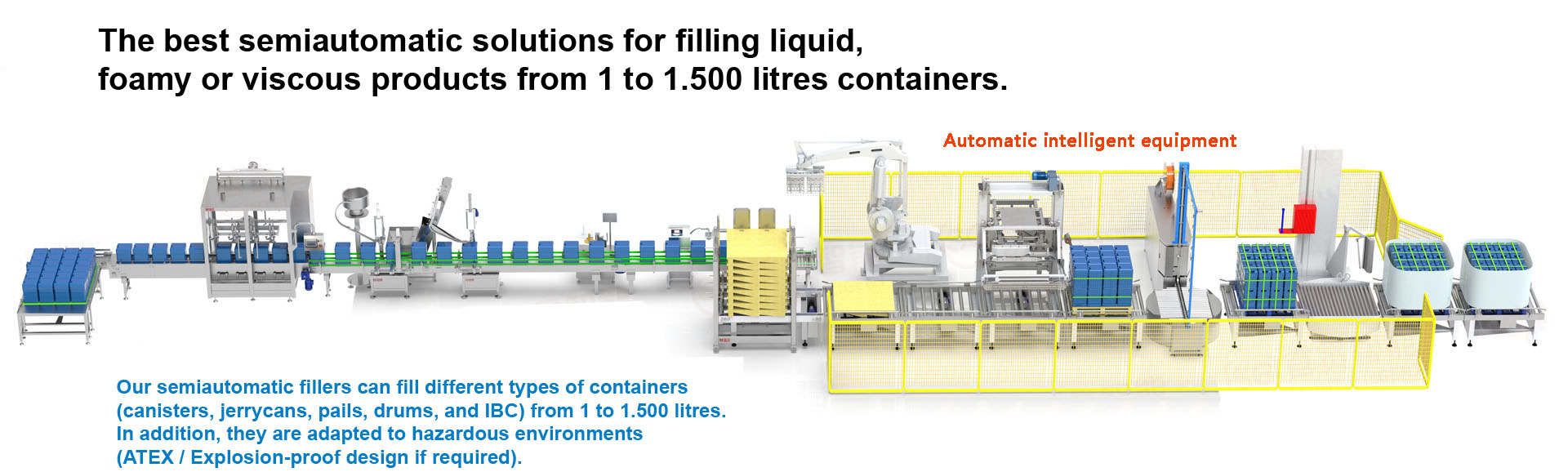

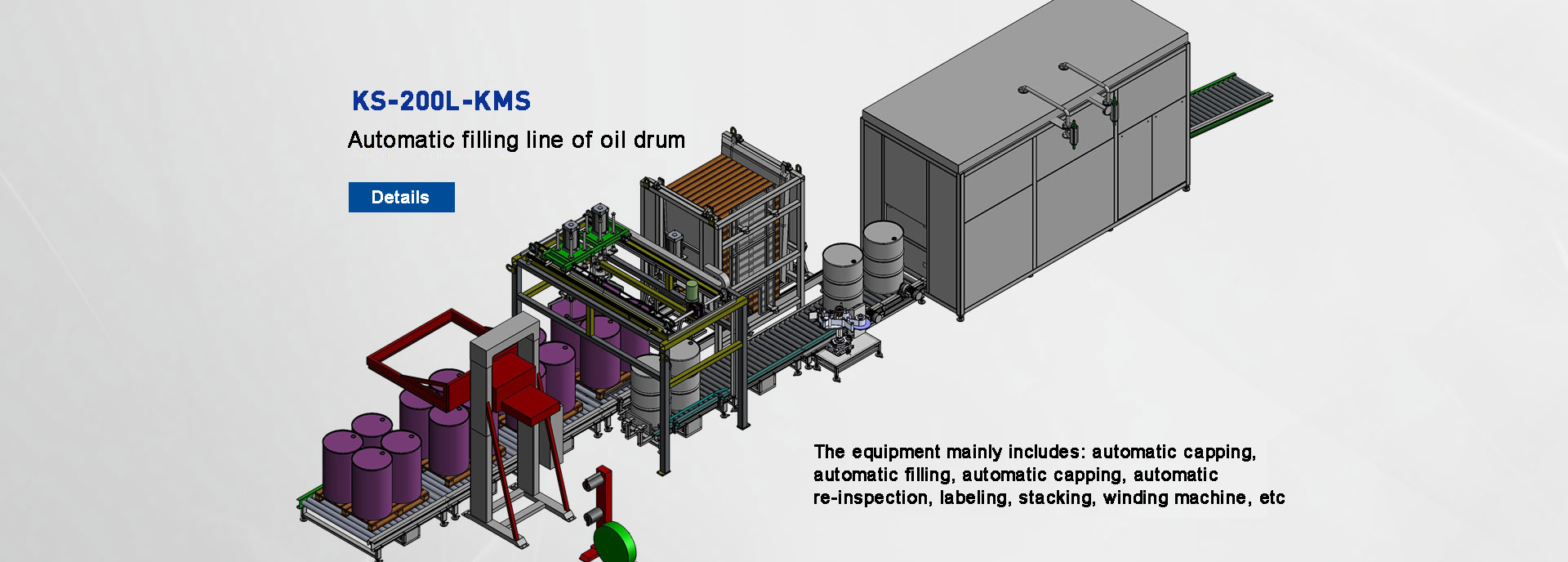

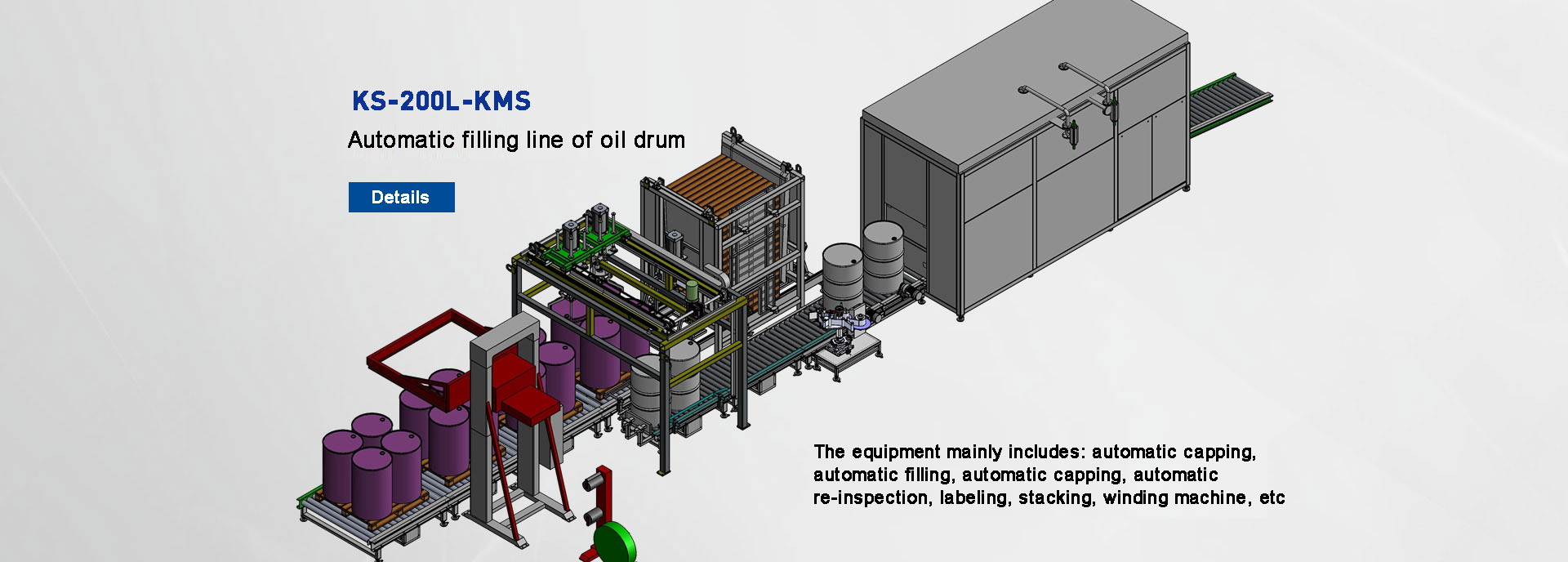

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance